Silicone Sealant Production Line Established In The UAE | JCT Machinery

Oct 22,2025

Oct 22,2025

JCT

JCT

Strong Market Demand: Driven by construction and infrastructure

1. Continues construction boom

The UAE is one of the most active regions in the world for construction investment. Cities like Dubai and Abu Dhabi consistently see a large number of high-rise curtain wall buildings, hotels, shopping malls, and infrastructure projects.

Silicone sealant, as an essential material for sealing curtain walls, glass, aluminum profiles and stone, enjoy a high and stable market demand.

2. Growing demand for building maintenance and renovation

Many buildings are over 10 years old, and renovation, maintenance, and waterproofing projects are increasing. This is driving long-term demand for neutral silicone, structural adhesive, and mildew-proof sealants.

3. Local production can replace imports

Currently, most silicone sealants in the UAE market are imported from countries like China, India, and Turkey. Local production can reduce transportation and tariff costs, enhancing competitiveness.

Convenient raw material supply: Abundant petrochemical raw materials

1. Easily available raw materials such as silicone fluid, fillers adn crosslinkers

The UAE boasts a well-developed petrochemical industry, providing a stable supply of basic raw materials such as silicone fluid, solvents, plasticizers and catalysts.

Silica and titanium dioxide can be easily imported from Saudi Arabia, India and China.

2. Well-developed ports and logistics

Dubai Port and Jebel Ali Free Zone (JAFZA) are important trade hubs in the Middle East, offering competitive costs for both imported raw materials and exported finished products.

Friendly policies and investment environment

1. Supportive manufacturing policies

The UAE government actively encourages local manufacturing under its "Make it in the Emirates" initiative, with chemicals and construction materials being key sectors.

2. Incentive free zone policies

Setting up a factory in locations such as the JAFZA and the Ras Al Khaimah Economic Zone (RAKEZ) offers zero tariffs, 100% foreign ownership, and tzx incentives.

3. Low energy consumption

The UAE's relatively low energy prices make operating costs more competitive for production lines requiring thermal oil heating and stirring power.

Mature industrial support

1. Building materials cluster

The local area boasts numerous glass, aluminum profile, stone and window and door manufacturers, creating a direct upstream and downstream industrial chain.

2. Complete packaging and filling services

The local supply chain for paper tubes, aluminum tubes, and flexible film allows for local silicone sealant filling machines, packaging materials and label printing.

3. Equipment and technical support can be provided from China

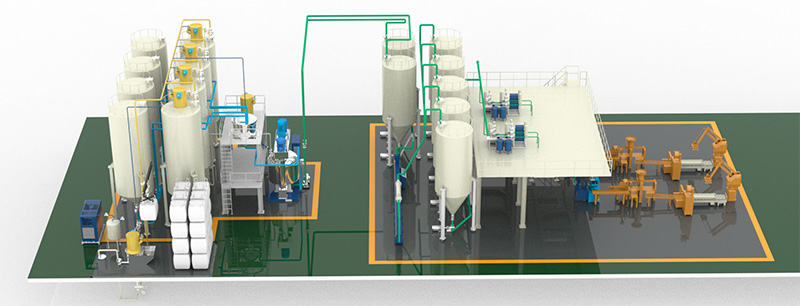

JCT offers complete silicone sealant production line turnkey project to help customers quickly commence production.

Huge export potential

1. Market access to the Middle East, Africa and South Asia

The UAE's advantageous geographical location allows for easy export to Saudi Arabia, Oman, Qatar, Kuwait, Egypt, Kenya, India and other regions.

2. Export advantages

Exporting under the "Made in UAE" designation avoids trade barriers imposed by some countries on Chinese products and significantly reduces shipping times.

If you are interested in JCT's silicone sealant production line turnkey project, feel free to contact us: +86-181 3837 3963 (Whatsapp, Wechat) or [email protected].

CN

CN

HOME

HOME How To Adjust The Viscosity Of Hot Melt Glue? | JCT Machinery

How To Adjust The Viscosity Of Hot Melt Glue? | JCT Machinery  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address