How To Adjust The Viscosity Of Hot Melt Glue? | JCT Machinery

Oct 24,2025

Oct 24,2025

JCT

JCT

Factors Affecting Hot Melt Adhesive Viscosity

The viscosity of hot melt adhesives in the heated state (typically measured at 150–200°C) is affected by the following factors:

- Main resin (binder) type and molecular weight

- Tackifier ratio and softening point

- Wax or oil additive content

- Temperature and shear rate

- Aging and oxidation

Method for Adjusting Viscosity Through Formula

1. Adjust the main resin ratio and type

Increasing the base resin content or choosing high-molecular-weight EVA, PO, TPR, etc. → Increased viscosity and tougher colloid.

Reducing the base resin ratio or choosing a low-molecular-weight resin → Lowered viscosity and improved fluidity.

2. Adjusting the Tackifier

Tackifier resins (such as C5/C9 petroleum resins and rosin-modified resins) can alter the fluidity of hot melt adhesives.

Adding a low-softening-point resin reduces viscosity.

Using a high-softening-point resin or increasing the proportion increases viscosity and enhances initial tack.

3. Control wax content

Wax is an important modifier for controlling fluidity:

Increasing wax content → reduces viscosity, accelerates flow, and shortens open time.

Reducing wax content → increases viscosity and extends open time.

4. Use plasticizers or softeners

In some systems (such as SBS and SIS hot melt pressure sensitive glue):

Adding plasticizer oils (such as white oil or terpene oils) → reduces viscosity and improves flexibility.

However, excessive amounts can result in excessively high cold tack and reduced heat resistance.

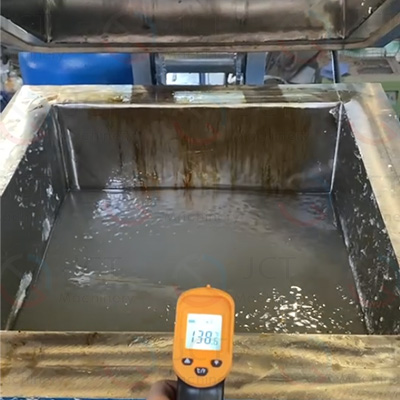

5. Temperature control

Hot melt glue viscosity is inversely proportional to temperature:

Increase in temperature → decrease in viscosity.

Decrease in temperature → increase in viscosity.

Viscosity Stability Controlled Through Equipment and Process Control

- Sigma mixer/reactor jacket temperature control system: Maintains constant temperature to prevent local overheating.

- Stirring speed and shear force: High shear can temporarily reduce viscosity, but air entrapment must be prevented.

- Vacuum degassin system: Removes gas, improves flowability and clarity.

- Online viscosity monitoring system (available on high-end production line) automatically adjusts temperature and ingredients.

JCT provide hot melt glue production line equipments and formula. You can send hot melt glue samples and we will help you to detect the raw material formula. The formula purchased from JCT supports permanent free upgrades.

CN

CN

HOME

HOME New Design Triple Shaft Mixer | JCT Machinery

New Design Triple Shaft Mixer | JCT Machinery  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address