Key Points For Inspection Before Hot Melt Glue Production Line Goes Into Production | JCT Machinery

Oct 17,2025

Oct 17,2025

JCT

JCT

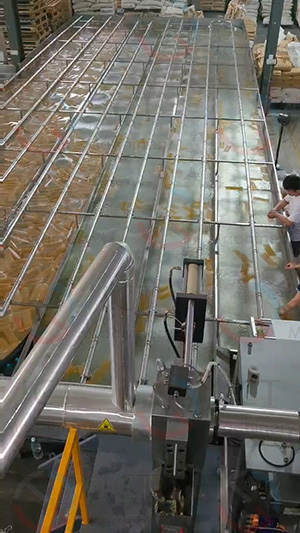

Preliminary inspection after installation (static inspection)

1. Equipment Appearance and Connections

- All equipment (sigma mixer, reactor, extruder, transfer pump, molding system, cooling system, etc.) must be free of damage, deformation or rust.

- All flanges, bolts and seals must be securely installed and tightened.

- Pipelines must be properly connected, with clear flow direction markings (especially for thermal oil, cooling water and vacuum lines).

- Cables must be neatly routed, protective conduits must be intact, and no exposed wires or damaged casings should be present.

2. Safety Devices and Protective Measures

- The safety valve, pressure gauge, and thermometer are all installed and readings are normal.

- The emergency stop switch is functioning properly and clearly located.

- External protective covers for all rotating components (such as the extruder screw and agitator shaft) are fully installed.

- The grounding wire and insulation resistance test have passed (≥1MΩ).

Electrical and Control System Inspection

1. Control System

- Before powering on the electrical control cabinet, inspect the interior for loose components or debris.

- Check that communication between the PLC, inverter, temperature control module and touch screen is normal.

- In manual operation mode, confirm that the rotation direction of each motor is correct (especially the agitator motor and extruder screw motor).

- Ensure that the temperature controller, pressure sensor, level gauge, and other sensors are accurately collecting signals.

2. Protection and Alarm System

- Simulate overtemperature, overvoltage, phase loss, and overload to verify that the alarm is triggered.

- Check the overtemperature power-off protection of the thermal oil heating system.

- Confirm that the vacuum system's backflow prevention device and vacuum valve are functioning and reliable.

Mechanical and Transmission Inspection

1. Agitation and Transmission

- Manually rotate the agitator shaft or screw to ensure there is no binding or unusual noise.

- Check the lubricating oil level in the bearings and reducer to ensure it meets the specified level.

- Check seals (such as mechanical seals and packing seals) for leaks.

2. Transmission Coupling

- Alignment accuracy meets requirements (coaxiality deviation ≤ 0.1mm).

- Fix the screws with lock washers and tighten securely.

No-load Test Run Sequence

- Start the thermal oil circulation heating system and test the heating rate and temperature control accuracy.

- Start the motors of each device and run them for 5–10 minutes.

- Check for vibration, abnormal noise, and overheating.

- Check the coordination of the temperature control, mixing, vacuum, discharging, and pelletizing systems.

No-load Operation Requirements

- Temperature fluctuation at each control point ≤ ±2℃.

- Stable stirring speed, no noticeable noise.

- No oil, water, or air leakage.

- Current within rated range.

Preparations For A Trial Run With Material

After heating to the set temperature according to process requirements:

- Check the temperature difference between each heating zone.

- Simulate the feeding process (a small amount of raw material or simulated material).

- Confirm that the material discharge is smooth, the temperature control is stable, and there are no signs of material stagnation or burning.

Final Confirmation Before Official Material Loading

- All safety devices have passed testing.

- No-load operating current, temperature, and vacuum baseline data have been recorded.

- All systems' cooling cycles are normal.

- Operator training has been completed, clarifying job responsibilities and operating procedures.

CN

CN

HOME

HOME Silicone Sealant Production Line Established In The UAE | JCT Machinery

Silicone Sealant Production Line Established In The UAE | JCT Machinery  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address