FAQ About Epoxy Resin Production Line | JCT Machinery

Oct 14,2025

Oct 14,2025

JCT

JCT

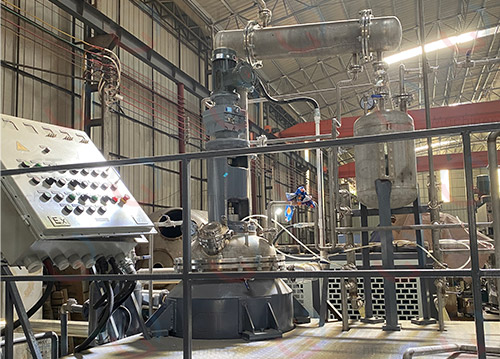

What equipments do the epoxy resin production line mainly consist of?

- Raw material storage tank

- Stainless steel reactor

- Temperactur control device

- Vacuum system

- Powder and liquid metering and conerying line

- PLC control system

- Acomplete set of pipes, valves and pumps.

How does an epoxy resin production line work?

Through a precise, automated, and sealed process, liquid epoxy resin (Part A) is uniformly mixed with a curing agent (Part B) and other additives in the correct proportions under a controlled environment. Air bubbles are removed, resulting in a homogeneous, ready-to-use product.

How to effectively remove bubbles in epoxy resin production?

The main mixing vessel itself is designed with a vacuum-capable structure, enabling integrated mixing and initial degassing.

A dedicated vacuum degassing vessel is connected in series after the mixing vessel for advanced degassing.

For continuous production lines, an inline vacuum degassing system is used.

The mixing and degassing vessels are equipped with a precise jacket temperature control system (mold temperature controller) to achieve precise control of heating and viscosity reduction.

The filling machine uses bottom filling or pressure filling to prevent the generation of new bubbles during the filling process.

How can epoxy resin production line control temperature to prevent over-reaction?

1. Reactor with jacket and pipe coil

The jacket and internal pipe coil can be used as heating or cooling circuits, providing a large heat exchange area.

2. Thermal oil/steam and cooling water

The thermal oil is used for high-temperature heating, while cooling water/cooling tower is used for rapid heat release; low-temperature chiller can be used as an auxiliary device if necessary.

3. Heat exchanger (plate or shell and tube)

Used to extract high-temperature media from the reactor circuit for side cooling or heat recovery.

4. Forced circulation pump and bypass cooling circuit

Ensure sufficient flow rate in the jacket or pipe coil to prevent local overheating.

5. Rate-limited dosing

Add reactants and curing agent in stages to control the instantaneous heat release rate and avoid dosing all at onece.

Use a metering pumo and a gradual dosing strategy (e.g., dosing according to a rate curve) for the curing agent/catalyst.

What is the difference between fully automatic and semi-automatic epoxy resin production line?

| Customer type | Recommended production line type | Reason |

| Large-scale chemical plants/resin exporter | Fully automatic | Strong stability, consistent quality, labor savings, and easy management and traceability |

| Small- to medium-sized plants/multi-product small-batch production company | Semi-automatic | Low cost, high flexibility and easy process adjustment |

| R&D institution/laboratory | Semi-automatic | Suitable for frequent recipe changes and process validation |

| Company planning gradual upgrading | Semi-automatic + reserved automation interface | Fully automated upgrades with the ability to add weighing modules and PLC systems later |

Can you provide epoxy resin production line turnkey project?

YES! We can offers epoxy resin production line turnkey project. From initial design to equipment manufacturing, installation and commissioning, formula guidance, and personnel training, we provide comprehensive , one-stop services.

- Save time and costs, eliminating the need for multi-party coordination.

- Ensure the stability and safety of your production line from design to commissioning.

- Suitable for investors seeking rapid entry into the epoxy resin market or for factory expansion projects.

CN

CN

HOME

HOME Ribbon Blender Manufacturer | JCT Machinery

Ribbon Blender Manufacturer | JCT Machinery  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address