Ribbon Blender Manufacturer | JCT Machinery

Sep 28,2025

Sep 28,2025

JCT

JCT

Introduction

Ribbon blender is a device used for continuous or intermittent mixing of dry powders, granules, and small amounts of liquid. It consists of two layers of inner and outer ribbons (or spirals), which generate convection and axial agitation within the mixer, achieving rapid and uniform mixing.

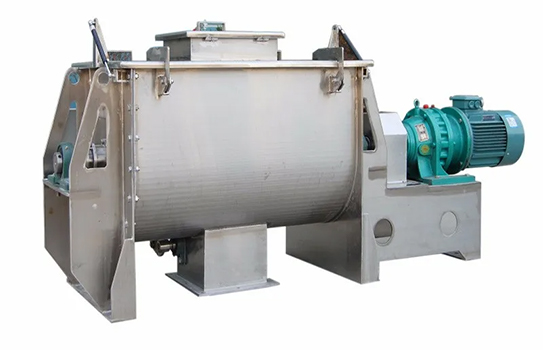

Ribbon Blender Structure

- Barrel (Mixing Tank): Horizontal, oval or cylindrical, with access doors and cleaning ports.

- Double-layer helical ribbon blades (inner and outer ribbons): The outer ribbon pushes the material toward the barrel wall, while the inner ribbon pulls the material toward the center, creating an axial circulation system.

- Spindle and geared motor: Provides stable, low-speed, high-torque drive; often equipped with variable frequency drive.

- Seals: Mechanical seals or packing seals at the shaft end prevent dust and leaks.

- Discharge Device: Bottom or end discharge valves (butterfly valve, ball valve, or pneumatic valve) facilitate unloading.

- Jacket/heating and cooling system (optional): Provides temperature control (heating or cooling).

- Vacuum/venting port (optional): Provides degassing or ventilation.

Ribbon Blender Working Principle

Ribbon blender features twin ribbons arranged on the same axis, rotating in opposite or same directions (typically the inner ribbon and outer ribbon run in opposite directions). The outer ribbon pushes the material toward the barrel wall and conveys it toward one end, while the inner ribbon pulls the material back toward the center from both ends. This combined radial and axial flow creates intense convection, resulting in rapid and uniform mixing of powders. The ribbons can also achieve uniform wetting in wet mixing systems containing small amounts of liquid.

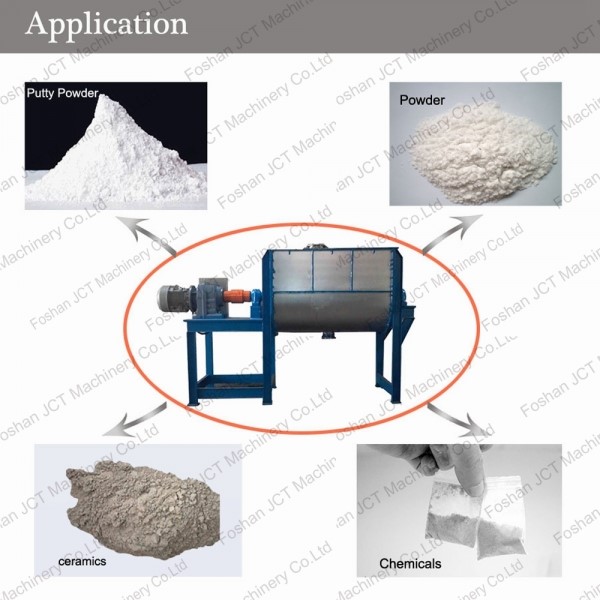

Suitable Materials for Ribbon Blender

- Dry powders and granules: plastic powder, resin powder, fillers (calcium carbonate, talc), pigments, dry rubber powder, etc.

- Wet mix systems containing small amounts of liquid: feed formulations, pre-granulation premixes, and oil/binder additions.

Ribbon blender is ideal for materials that are not susceptible to strong shear (to avoid breakage).

Advantages of Ribbon Blender

- Uniform mixing and high efficiency: Suitable for uniform mixing of large batches with short mixing times.

- Low shear: Gentle processing without damaging particle morphology or coatings.

- Simple structure and easy maintenance: Easy to repair and long service life.

- Low energy consumption: Low-speed, high-torque design saves energy.

- Scalable/customizable: Jackets, dosing nozzles, vacuum, or automatic dosing systems can be added.

JCT Machinery is a professional manufacturer of horizontal ribbon mixers. We offer a full range of products, from small laboratory units to large industrial units, with custom designs available. They are widely used for mixing powders, granules, and small amounts of liquids. Factory direct sales guarantee quality, serving customers worldwide.

CN

CN

HOME

HOME National Day And Mid-Autumn Festival Holiday Notice | JCT Machinery

National Day And Mid-Autumn Festival Holiday Notice | JCT Machinery  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address