The epidemic has caused the rise of the pharmaceutical industry. What machinery and equipment are used to make medicine?

This sudden epidemic has had a huge impact on all industries. Some industries have found opportunities to develop very well during the crisis. Some industries are in deep crisis and are seeking a turnaround. The pharmaceutical industry has received u

Oct 30,2021

Oct 30,2021

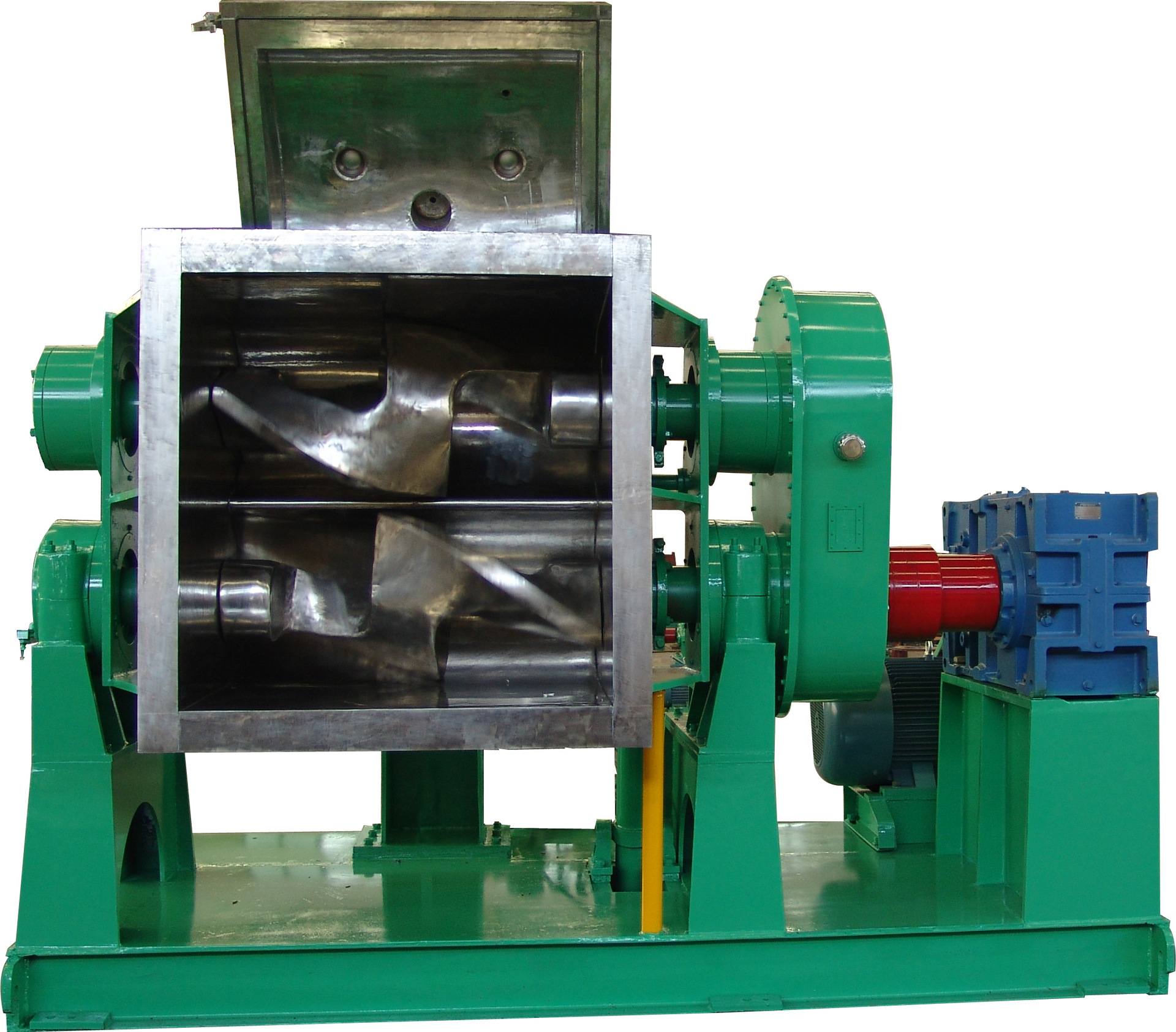

Power mixer capable of making paste cosmetics

Power mixers are widely used in solid-solid, solid-liquid, liquid-liquid material mixing, reaction, dispersion, grinding, dissolution, homogenization, Processes such as emulsification. It is an ideal equipment for the production of inks, pigments, ad

Oct 27,2021

Oct 27,2021

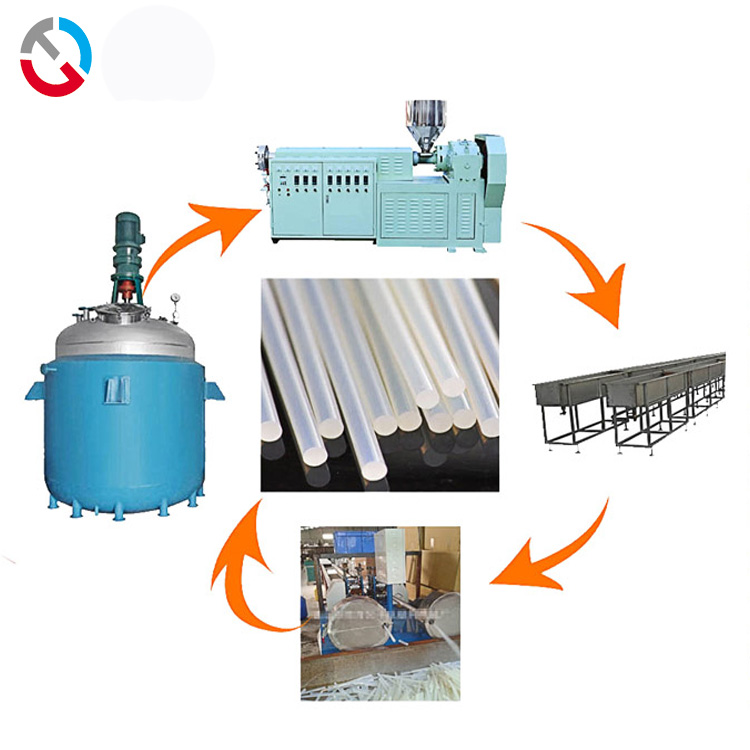

A good reactor determines the quality of hot melt glue sticks?

The hot melt glue stick is white and opaque (strong type), non-toxic, easy to operate, and there is no carbonization in continuous use……

Oct 27,2021

Oct 27,2021

What is a hydraulic discharge machine?

The hydraulic discharging machine is a hydraulic filling equipment that is used in conjunction with planetary mixers, power mixers and powerful dispersers to fill materials with a certain fluidity, and is especially suitable for pressurized tanks of

Oct 26,2021

Oct 26,2021

In the chemical industry if you want high profits, you should use reactors to produce PVA

PVA prices will increase by RMB 2,000/ton starting today……

Oct 26,2021

Oct 26,2021

What is a horizontal ribbon mixer?

The horizontal ribbon mixer is composed of a U-shaped container, ribbon mixing blades and transmission components; ribbons are divided into continuous and disconnected types. The ribbon blades are generally made of double or triple layers, and the ou

Oct 25,2021

Oct 25,2021

What is the most profitable product currently produced by the reactor?

In the last 30 days, the price of chemical raw materials with reactors as the main production machine has risen by 20%. This chemical raw material is a...

Oct 25,2021

Oct 25,2021

CN

CN

HOME

HOME

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address