When the reactor tank appears to seal leak, how can we solve?

Jul 21,2017

Jul 21,2017

JCT

JCT

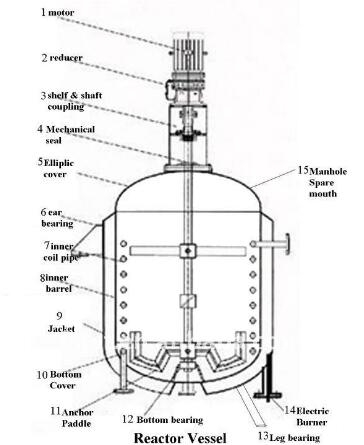

With the continuous development of the chemical industry, the use of the reactor is more and more. However, due to some uncontrollable factors, improper maintenance of staff operations, the use of time and so on, will affect the reactor seal, resulting in the reactor does not work or there are security risks. When the reactor tank appears to seal leak, how can we solve?

1. The stirring shaft is worn or corroded at the filler, causing the gap to be too large

2. Oil ring location not suitable or blockage can not form oil seal

3. Gland can not press tightly, poor quality for filler, or used for a long

4. Filler container is corroded

When using mechanical seals

1. The deformation or damage of the surface of the static and dynamic ring

2. Surface than the pressure is too large, friction generated thermal deformation

3. Seal ring selection is not right, the pressing force is not enough, or V-shaped ring mounted anti, loss of sealing

4. The vertical error of the axis and the static ring surface is too large

5. Operating pressure, temperature instability, hard particles into the friction involved

6. The amount of shaft string exceeds the target

7. seam leakage in the inlaid or adhesive dynamic, static ring

For the first case

1. Replace or repair the stirring shaft and machine on the machine to ensure roughness

2. Adjust the oil ring position and clean the oil path

3. Compress the packing, or replace the packing

4. A repaired or replaced

For the second case

1. Replace the friction pair or re-grinding

2. Adjust the pressure to be appropriate to strengthen the cooling system, take away the heat in time

3. Seal ring selection, installation should be reasonable, have enough compression force

4. stop, re-find, to ensure that the vertical is less than 0.5mm

5. Strict control of process indicators, particles and crystallization can not enter the friction pair

6. Adjust the maintenance of the shaft to achieve the amount of channeling

7. Improve the installation process, or the amount of interference should be appropriate, or adhesive to be easy to use, solid

When the reactor tank appears to seal leak, how can we solve? If you face with problems like these above, welcome to consult to us!

CN

CN

HOME

HOME

Do you know how to deal with these conditions when the industrial fermenter mixing reactor is in use?

Do you know how to deal with these conditions when the industrial fermenter mixing reactor is in use?  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address