PVA Production Line Complete Equipment Supplier | JCT Machinery

Aug 12,2025

Aug 12,2025

JCT

JCT

What is PVA?

PVA (Polyvinyl Alcohol) is a water-soluble synthetic polymer made from polyvinyl acetate (PVAc) through alcoholysis or hydrolysis. It is one of the few water-soluble polymer material.

Key Properities of PVA

- Solubility: Soluble in water (solubility affected by alcoholysis degree), insoluble in organic solvents (such as acetone and gasoline).

- Film-forming: Forms strong, transparent, non-toxic films.

- Adhesion: Excellent adhesion to cellulose (paper,wood) and porous materials.

- Chemical resistance: Resistant to oils. greases and solvents but decomposes in strong acids and bases.

- Environmental: Biodegradable (microbial degragation into CO₂ and H₂O).

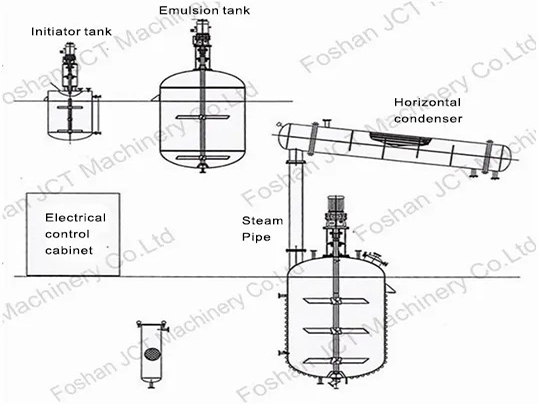

Main Equipment of PVA Production Line

- Storage tank: With stirring and nitrogen protection to prevent pre-polymerization, temperature control 20-30℃ (to avoid gelation).

- Alcoholysis reactor: Materials contact surface is made of SS304/316, resistant to alkali corrosion. Anchor agitator+baffle (mixing efficiency >95%). Double-layer jacket (thermal oil temperature control ±0.5℃). Vacuum system (for degassing and methanol recovery).

- Sedimentation washing tank: Multi-stage countercurrent washing (removal of sodium acetate impurities).

PVA Production Line Technical Highlight

1. Precise alcoholysis degree control

Real-time adjustment of alcoholysis degree (control accuracy ±1%) through the combination of an online viscometer and near-infrared spectroscopy.

2. Energy-saving design

Reaction heat is used to preheat raw materials (15% energy savings).

Waste heat recovery from drying exhause gas.

3. Intelligent control

Automatic recipe recall (supports storage of over 100 recipes).

Fault self-diagnosis (e.g., warning of abnormal stirring torque).

Why choose JCT's PVA production line turnkey project?

✔️ 20+ years of industry experience

✔️ Modular design, supports fucture expansion and upgrades

✔️ Global service network, 8-hour emergency response.

CN

CN

HOME

HOME PU Glue Triple Shaft Mixer Manufacturer | JCT Machinery

PU Glue Triple Shaft Mixer Manufacturer | JCT Machinery  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address