Introduction Of Sigma Mixer Drive System | JCT Machinery

Oct 08,2025

Oct 08,2025

JCT

JCT

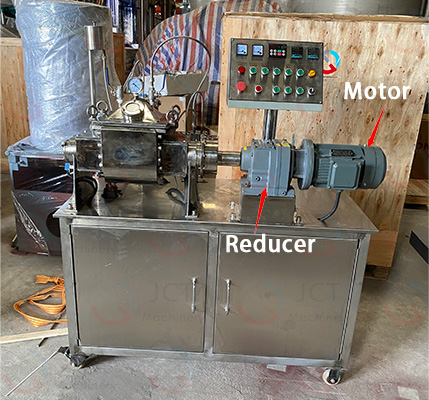

In sigma mixer, the motor and reducer are the main parts of the drive system. Together, they determine the speed and torque of the blades and the mixing performance of the entire sigma mixer.

Motor

Definition: Motor is sigma mixer's power source, responsible for converting electrical energy into mechanical energy.

Function:

- Provide stirring power: Enabling two ∑-shaped blades to powerfully knead, shear and mix.

- Controls speed and output power: Adjusts speed via a frequency converter to accommodate materials of varying viscosities or stages.

- Ensures stable operation: High torque output prevents motor stalling or burnout when the material is too thick.

Motor determines "whether it can rotate" and "how fast it can rotate".

Reducer

Definition: Reducer is connected between motor and the main shaft.

Function:

1. Reduces speed and increases torque

Motor speed is typically around 1440rpm, while sigma mixer's blade shaft typically only operates at 20-40rom.

Reducer converts high speed into low speed, high torque output through gear transmission.

2. Ensures synchronization and stability

The two counter-rotating blades maintain a precise speed difference through a gear synchronization mechanism, ensuring uniform kneading of the material.

3. Extends equipment life

Reducer also absorbs some shock loads, protecting the motor from demage caused by transient torque shocks.

Reducer determines "how stable the rotation is" and "whether the power is strong enough".

Working Principle of Sigma Mixer's Motor and Reducer

- Motor outputs high-speed rotation (approximately 1440rpm).

- Reducer reduces the speed (to 20-40rpm) and amplifies the torque.

- The shaft drives two ∑-shaped blades in opposite directions at a certain speed difference, generating strong shear and extrusion forces.

- This achieves kneading, mixing, plasticizing or reaction processes for the material.

Our sigma mixer is ideal for producing high-viscosity, high-solids materials such as hot melt glue, butyl rubber, sealants, silicone rubber, and chewing gum.

Sigma mixer utilizes a double ∑-shaped blades structure, equipped with a powerful motor and a reducer, enabling uniform kneading and mixing under intense shear and pressure.

JCT can customize the mixing speed, heating method (electric, thermal oil, steam), and discharge system to meet your process requirements, providing you with a stable and efficient sigma mixer (5L-2000L, special capacity can be designed according to customer's requirements).

Contact us for more sigma mixer information: +86-181 3837 3963 (Whatsapp, Wechat) or [email protected].

CN

CN

HOME

HOME Uncover The Advantages Of Ribbon Mixer In Chemical Production | JCT Machinery

Uncover The Advantages Of Ribbon Mixer In Chemical Production | JCT Machinery  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address