How To Choose The Discharge Type Of Sigma Mixer? | JCT Machinery

Nov 19,2025

Nov 19,2025

JCT

JCT

As sigma mixer manufacturer, JCT has summarized several common sigma mixer discharge typrs to provide you with a reference when purchasing sigma mixer.

Common Discharge Types of Simga Mixer

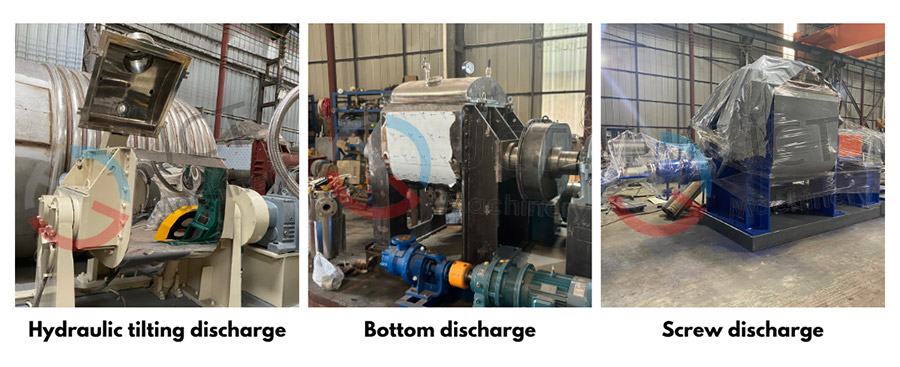

1. Hydraulic Tilting Discharge

Sigma mixer rotates completely to discharge the material.

- Suitable for high-viscosity, semi-solid, and even lumpy materials.

- Fast discharge speed.

- Easy cleaning.

- Simpl manual operation.

Suitable materials: Hot melt glue, butyl rubber, high-viscosity rubber, sealants, chewing gum base, resins, etc.

2. Hydraulic Bottom Discharge

Materials are pushed through a bottom valve, with hydraulic control.

- Suitable for materials with good flowability or medium viscosity.

- More precise discharge, suitable for connecting to subsequent pumping or molding processes.

- A more enclosed and cleaner production process.

Suitable materials: Paints, putties, high-viscosity slurries, food base materials, hot melt glue, etc.

3. Manual bottom valve

Manually open the bottom valve to discharge material.

- Lowest cost

- Flexible operation and simple structure

Suitable materials: Medium flowability, non-hazardous materials, laboratory use.

4. Screw discharge

Sigma mixer has an extrusion device at the bottom, extruded by a screw or pusher plate.

- Even materials with extremely high viscosity can be extruded.

- The discharge is uniform and controllable, suitable for continuous production.

- Suitable for drum or strip forming processes.

Suitable materials: Butyl sealant, rubber base material, ultra-high viscosity sealant, aviation adhesive, modeling clay, rubber putty, etc.

Key factors in choosing the discharge type for sigma mixer are:

- Material viscosity

- Flowability

- Whether it needs to be connected to the nect process

- Labor and hygiene requirements

- Budge and floor space requirements

Comparison of the advantages and discharges of different discharge methods

| Discharge types | Advantages | Disadvantages |

| Hydraulic tilting discharge | Highly versatile, suitable for high viscosity, easy to clean | Slightly larger soace required |

| Hydraulic bottom discharge | More enclosed and cleaner, suitable for integration with production lines | Unsuitable for extremely high viscosity materials |

| Manual bottom valve | Most suitable for ultra-high viscosity and quantitative dispensing | Higher cost and more complex structure |

| Screw discharge | Lowest cost | Unsuitable for high viscosity materials, low efficiency |

If you require recommendations for different sigma mixers (5L~2500L, or design according to actual need) configurations, please contact JCT: +86-18138373963 (Whatsapp, Wechat) or [email protected].

CN

CN

HOME

HOME High-efficiency, Low-energy White Glue Production Line | JCT Machinery

High-efficiency, Low-energy White Glue Production Line | JCT Machinery  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address