Double Planetary Mixer For Resin Making | JCT Machinery

Apr 22,2025

Apr 22,2025

JCT

JCT

Double planetary mixer is suitable for producing resin products:

1. Epoxy resin

Double planetary structure can achieve uniform mixing without dead corner, suitable for high viscosity materials.

2. Polyurethane resin

Effectively avoid bubbles and improve reaction stability.

3. Silicone resin

Excellent mixing and degassing effect on high viscosity and thixotropic materials.

4. Acrylic modified resin

Suitable for complex systems of mixed resin, tackier and initiator.

5. Phenolic resin

Traditional equipment is difficult to mix evenly, and double planetary mixer adapts to viscosity changes.

6. Polyester resin

Fillers can be mixed under vacuum to avoid bubble entrainment.

7. Polyester polyol

Suitable for mixing raw materials in a solvent-free, reactive environment.

Advantages of Double Planetary Mixer

- Wide application range: Double planetary mixer can process everything from viscous liquids to semi-solids.

- Good mixing effect: Revolution + rotation, achieving three-dimensional mixing.

- Vacuum mixing: Double planetary mixer can eliminate bubbles, suitable for resin products that are sensitive to bubbles.

- Strong temperature control capability: Supports jacket heating and cooling, and the reaction is more controllable.

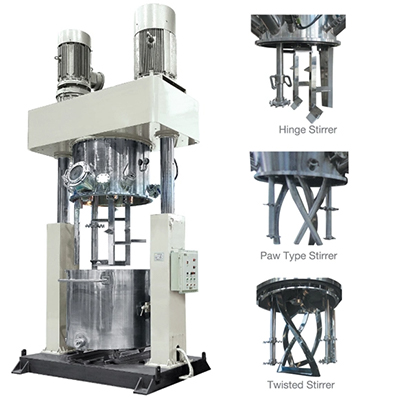

Key Design Features of Resin-specific Double Planetary Mixer

1. High torque drive system

For high-viscosity resins (such as epoxy resin, polyurethane, phenolic, etc.), a reinforces reducer and high-power motor are configured to ensure that the equipment can continue to operate stably even under full load and high viscosity.

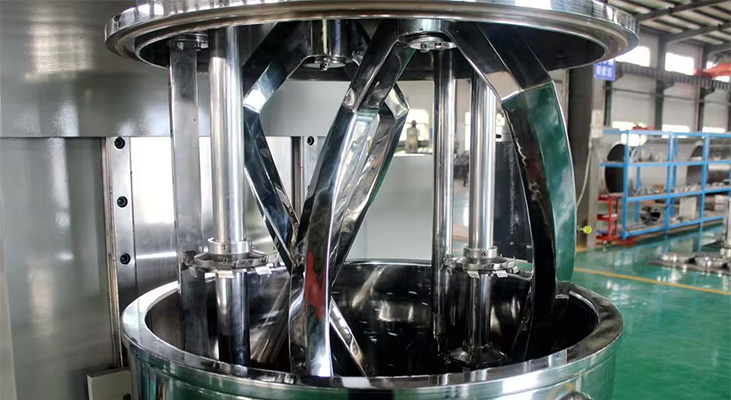

2. Special blade structure

Optional twisted blade, folding blade, dispersing disc and other forms are available to enhance shear force and dispersion efficiency.

The blades are precisely processed and polished to prevent material from hanging on the wall and residue, making it easy to clean.

3. High-fit scraping wall design

Configure a scraper mechanism or make the stirring blade highly fit with the cylinder wall to effectively prevent material agglomeration and dead corner residue, and improve mixing uniformity.

4. Vacuum sealing system

Equipped with a vacuum degassing device, double planetary mixer can effectively remove air when mixing resins, improve the transparency, physical properties and yield of the resin.

5. Precise temperature control jacket

Double planetary mixer is equipped with a jacket heating/cooling system, which can be selected by electric heating, thermal oil or water circulation to ensure that the reaction or mixing temperature is controlled within the optimal range to prevent premature curing of the resin or abnormal performance.

CN

CN

HOME

HOME Folding Blade Double Planetary Mixer And Horizontal Ribbon Mixer | JCT Machinery

Folding Blade Double Planetary Mixer And Horizontal Ribbon Mixer | JCT Machinery  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address