Product Details

Application

Structural features

Technical Parameters

contact us

Have you ever been troubled by these R&D challenges?

- A carefully designed formula, only to have it completely transformed once it's on the production line?

- When faced with high-viscosity slurries or pastes, traditional mixers are completely inadequate, forcing you to rely on manual mixing, which is inefficient and results in inconsistent batches?

- Have you ever wasted precious experimental materials due to uneven mixing or excessive residue from the equipment?

What you need is not just a "mixer", but a bridge connecting the laboratory and the factory - 5L laboratory sigma mixer.

Main Value of 5L Laboratory Sigma Mixer

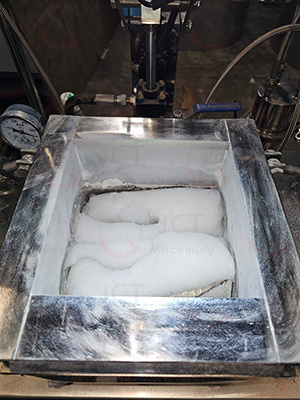

- Precise Process Scale-up Simulation: Laboratory 5L sigma mixer replicates the powerful shearing, squeezing, and folding effects of a large-scale sigma mixer, allowing you to predict material performance on the production line, significantly reducing industrialization risks and saving significant trial-and-error costs.

- Strong Material Adaptability: Designed to handle high-viscosity, high-solids materials. Whether it's battery slurry, silicone, sealant, ceramic slurry, or specialty inks and ointments, laboratory 5L sigma mixer cna easily handle it, solving mixing challenges that traditional equipment struggles with.

- R&D Efficiency Multiplier: Precisely controlling key parameters such as temperature, speed, and optional vacuum level allows for rapid formulation optimization and validation, shortening R&D cycles and helping you bring new products to market faster.

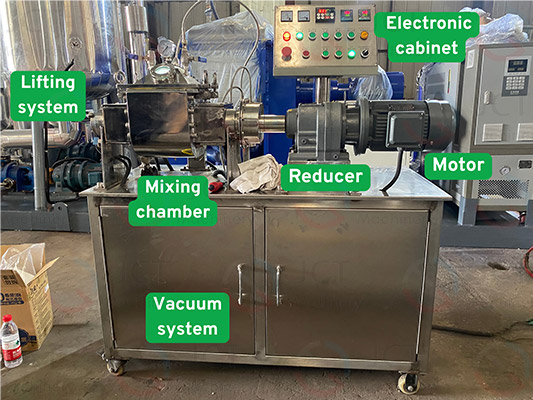

Structure of 5L Laboratory Sigma Mixer

5L Laboratory Sigma Mixer Features

- Flexibility: The tilting cylinder design makes feeding, unloading, and cleaning extremely convenient.

- Precision: Variable frequency speed regulation and an optional temperature control system allow for precise control of process parameters.

- Simulation: The operating principle is consistent with large-scale sigma mixer, ensuring that experimental data can be scaled up to production.

- Safety: Mechanical and electrical interlocks are typically included to prevent the machine from starting when the cylinder is tilted, ensuring operator safety.

Contact us on +86-181 3837 3963 (Whatsapp, Wechat) or [email protected]:

- Get free access to detailed product datasheets: Learn more about the specifications.

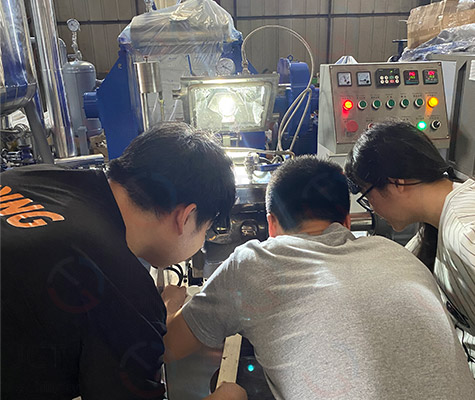

- Schedule an online technical chat: JCT's engineers will answer your specific questions.

- Request a free sample or submit your material for a free test: See the mixing results firsthand!

- New Energy: Research and development of positive and negative electrode slurries for lithium batteries and formulation optimization.

- Adhesives: Development of high-performance adhesives such as epoxy resins, silicones, and hot melt glue.

- Fine Chemicals: Uniform dispersion of inks, pigments, and sealants.

- Food Industry: Research on formulations for high-viscosity candies, chocolates and chewing gum.

Phone: +86-181 3837 3963 (Whatsapp, Wechat)

Email: [email protected]

CN

CN

HOME

HOME

Related Suggestion

Related Suggestion

Jul 25,2024

Jul 25,2024

Tel

Tel

Email

Email

Address

Address