1) Kneader is an ideal equipment for kneading, kneading, crushing, dispersing, and re-polymerizing high-viscosity elastoplastic materials. It has the advantages of uniform mixing and high kneading efficiency;

2) Stirring mode: Stirring by two different speed Paddle (Z-type or Σ-type) is strongly squeezed and sheared to make the materials mix evenly.

3) The kneader can be divided into three types: vacuum type, pressure type and normal pressure type.

4) Heating and cooling methods: heating oil heating, clamping Electric heating, steam heating, water cooling, etc.

5) Cover opening method: hydraulic cover opening.

6) Discharging method: hydraulic cylinder tilting, bottom discharging, screw extrusion, etc.

7) Various safety, measurement and control instruments can be installed on the equipment.

8) The parts in contact with the material are made of stainless steel, or according to the requirements of the buyer;

9) The stirring shaft seal adopts a vacuum structure. Preventing the packing filler particles from entering the cylinder body can ensure the quality and purity of the material.

It is widely used in high-viscosity sealants, silicone rubber, adhesives, BMC inks, pigments, dyes, plastics, rubber, cosmetics and other industries.

1. Transmission part:

1) Motor: 1.1-160KW (according to equipment size and product viscosity requirements); kneading machine above 2000L can adopt dual motor configuration;

2) Reducer: 1.1-55KW can be equipped with helical gear reducer, motor Reducer is directly connected; 22-160KW can be equipped with hard tooth surface cylindrical gear reducer;

3) Motor and reducer transmission mode: 1.1KW-22KW generally adopts direct connection, and above 22KW generally adopts belt drive (with buffer function)

4) Transmission of reducer and mixing shaft: cross slide coupling or spline coupling;

5) Transmission between mixing shaft: gear transmission, the number of gear teeth is different, and the speed ratio is generally about 1: 1.5;

2. Stirring paddles:

1) Mainly use Σ and Z type, usually use Σ type, special case: such as DMC and other products, it is required to reduce the shear of the product as much as possible.

2) Material: 5-50L kneader blades are all stainless steel, V≥100L kneader blades are generally made of cast steel with stainless steel plate;

3) Shaft seal: packing seal structure: hard PTFE tube + PTFE V-ring + PTFE packing; for the prevention of filler abrasion impurities entering the cylinder, a vacuum box structure can be added (principle: when the vacuum box and the kneader are evacuated at the same time, the vacuum box volume is smaller than the cylinder, the vacuum is faster, and the wear material is Pump to the vacuum box)

4) Stirring speed: fast propeller: slow propeller ≈48: 32 (V≤300L), ≈42: 28 (V≥500L), speed ratio ≈1.5: 1. Frequency converter can be used for speed regulation.

5) The stirring blade can rotate forward and reverse.

3. Cylinder block:

1) The inner block is W-shaped, the material is generally stainless steel, the outer jacket is heated and cooled, the two ends are detachable wall plates, and the material is thick carbon steel lined stainless steel plate; between the cylinder body and the wall plate Sealed with asbestos rubber sheet + sealant (polytetrafluoroethylene sheet (PTFE) for food and other high-demand products);

2) Cylinder head: arched, with feeding port, feeding port, vacuum port, sight glass, etc. Material: SS304 stainless steel; cover opening method is usually hydraulic opening cover, opening angle ≥ 75 °;

3) gap between mixing paddle and cylinder wall is 3-5mm, and gap between wall plate is 3mm; board.

4. Heating and cooling methods:

1) Jacket electric heating: 5L → 2KW, 50L → 6-9KW, 100L → 12-15KW, 200L → 15-18KW, 300L → 20-24KW, 500L → 24-36KW, 1000L → 36-42KW, 2000L and above are recommended to use heating furnace cycle heating.

2) Outer circulation heating: Electric heating furnace specifications: 12KW, 24KW, 30KW, 45KW, 60KW, 75KW, 90KW, 120KW, 150KW, etc. Generally need to be equipped with 2 sets of heat oil pump;

3) Steam heating: users must first request for steam heating It is put forward that different steam temperatures require completely different cylinder thicknesses and jacket pressure resistance requirements. The cylinder and jacket must be thickened, and the equipment price must be increased.

4) The jacket can be cooled by passing cold water. When the heat transfer oil is heated, it can be cooled by external oil cooler.

| Model |

Full volume |

Drive motor power(KW) |

discharge mode |

heating |

vacuum degree(mpa) |

remark |

| NHZ-2 |

2 |

0.75 |

turn cylinder |

hot oil/

power/

steam water cooling

|

|

|

| NHZ-5 |

5 |

1.1-2.2 |

|

|

| NHZ-10 |

10 |

1.5-3 |

|

|

| NHZ-20 |

20 |

3-5.5 |

|

|

| NHZ-50 |

50 |

4-7.5

|

-0.098 |

|

| NHZ-100 |

100 |

5.5-7.5 |

|

|

| NHZ-200 |

200 |

7.5-15 |

turn cylinde

the material under

screw the material

|

|

|

| NHZ-300 |

300 |

11-18.5 |

|

|

| NHZ-500 |

500 |

18.5-30 |

|

|

| NHZ-1000 |

1000 |

22-55 |

|

|

| NHZ-2000 |

2000 |

45-75 |

|

|

| NHZ-3000 |

3000 |

55-110 |

|

|

| NHZ-5000 |

|

|

|

|

5

Contact information:

If you need to know the detailed equipment configuration, production technology, production

process, please contact us.

Email:[email protected]

Mobile: 0086-181 3837 3963(WhatsApp, Wechat)

Address: Donglian Jincheng Industrial Zone, Danzao Town, Nanhai, Foshan, Guangdong, China.

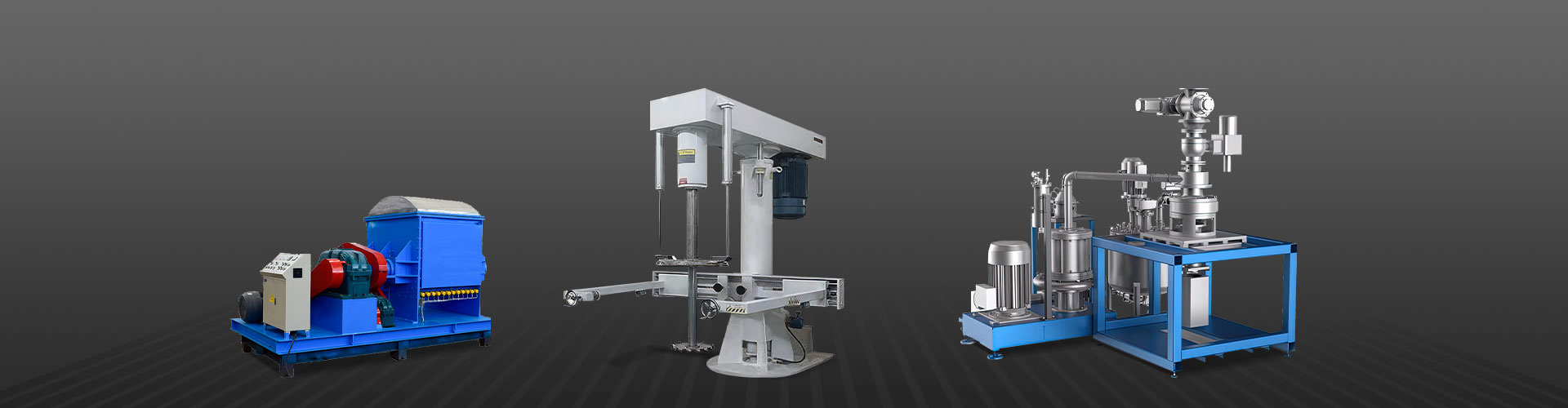

Product line

Product line sigma mixer

sigma mixer mixing tank

mixing tank Ribbon blender

Ribbon blender kneading machine

kneading machine Reactors

Reactors High-Shear Mixers

High-Shear Mixers

CN

CN

HOME

HOME

Related Suggestion

Related Suggestion

Jul 25,2024

Jul 25,2024

Tel

Tel

Email

Email

Address

Address