|

omo laundry detergent powder making machine

Product Description

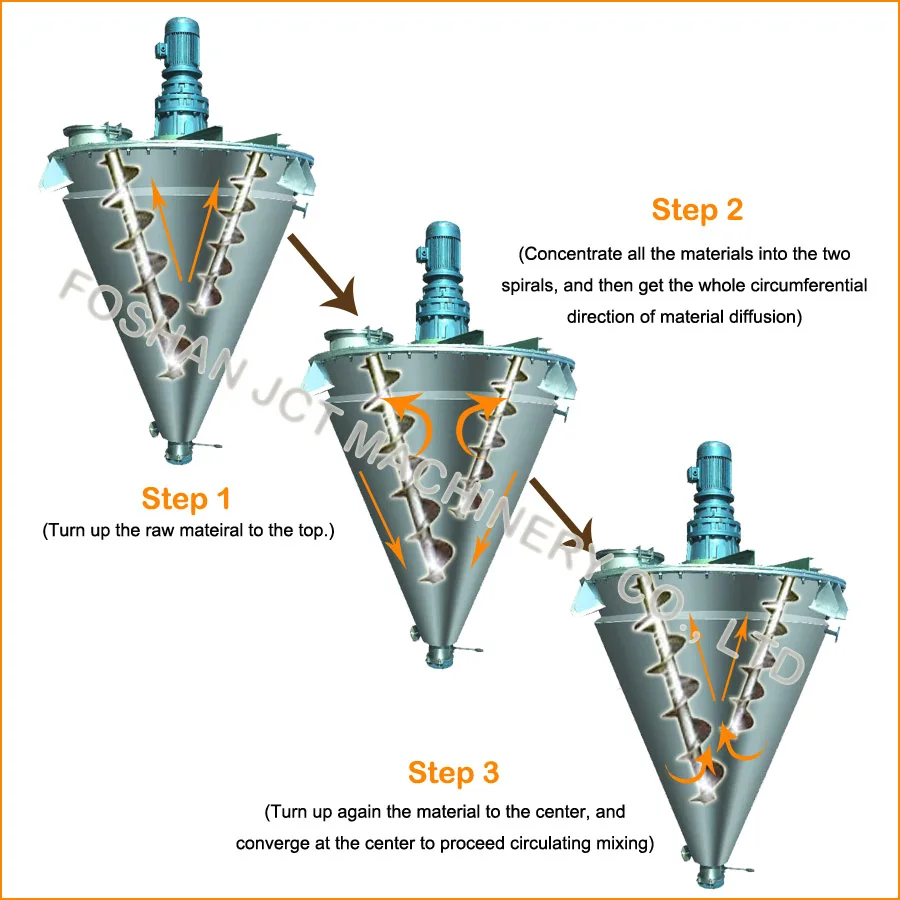

1. INTRODUCTION Twin-screw cone mixer is a new and efficient mixing equipment, especially for powder mixing. Widely use for Chemicals, pharmaceuticals, pesticides, fertilizers, dyes, metallurgy, mining, food, monosodium glutamate, feed and other industries. Suitable for solid - solid (powder and powder) mixing, solid - liquid (powder and liquid) mixing. 1. Mixing Method: Standard Twin-screw cone mixer has two stirring spirals. According to the requirements for production, you can choose single spiral (one long spiral), double spirals (a long and a short asymmetrical spirals) and three spirals (two short and one long symmetrical spirals). 2. Cooling and Heating System: Can equip with outer jacket for heating or cooling. Usally use water for cooling, steam/ thermal oil/ electric for heating. 3. Liquid-adding Mixing: Install liquid jet pipeline in the intermediate shaft of the mixer, connect the atomizing nozzle, which can adding liquid into the mixer; By selecting a specific material, you can add the acid and alkaline liquid material into the powder for mixing. 2. APPLICATION OF TWIN-SCREW CONE MIXER

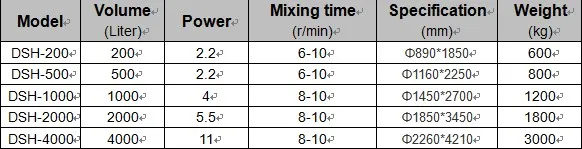

3. TECHNICAL PARAMETERS

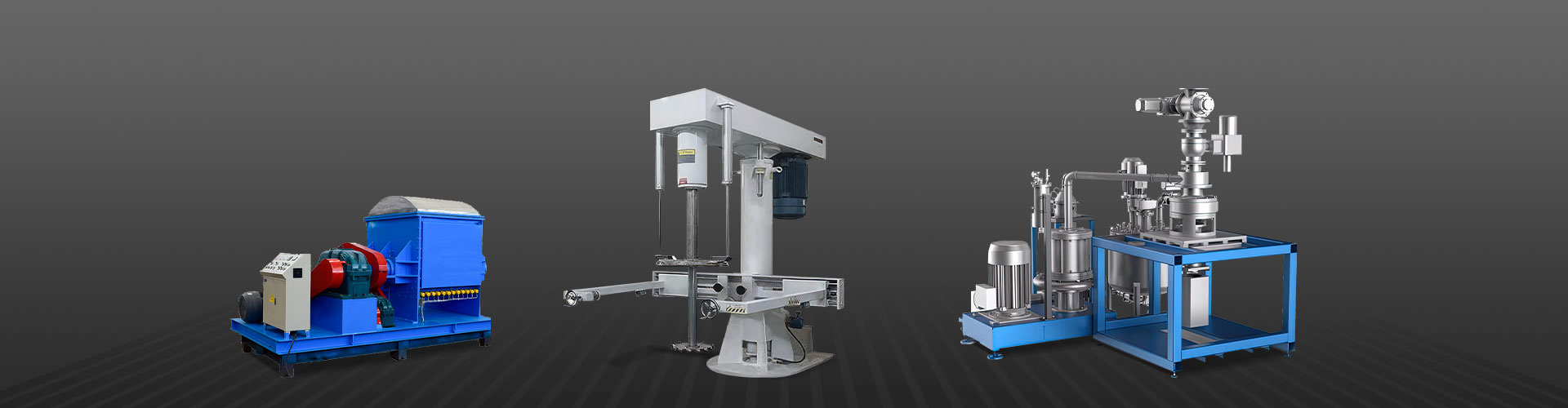

4. PICTURES picture 1

picture 2

blades for twin-screw cone mixer

FAQ

Packaging & Shipping

Company Information

5. WHY CHOOSE US Quality-assurance

Professional Sales team & Technology support & Strict processing department

Our Services

6. OUR CUSTOMERS

|

|

omo laundry detergent powder making machine

Product Description

1. INTRODUCTION Twin-screw cone mixer is a new and efficient mixing equipment, especially for powder mixing. Widely use for Chemicals, pharmaceuticals, pesticides, fertilizers, dyes, metallurgy, mining, food, monosodium glutamate, feed and other industries. Suitable for solid - solid (powder and powder) mixing, solid - liquid (powder and liquid) mixing. 1. Mixing Method: Standard Twin-screw cone mixer has two stirring spirals. According to the requirements for production, you can choose single spiral (one long spiral), double spirals (a long and a short asymmetrical spirals) and three spirals (two short and one long symmetrical spirals). 2. Cooling and Heating System: Can equip with outer jacket for heating or cooling. Usally use water for cooling, steam/ thermal oil/ electric for heating. 3. Liquid-adding Mixing: Install liquid jet pipeline in the intermediate shaft of the mixer, connect the atomizing nozzle, which can adding liquid into the mixer; By selecting a specific material, you can add the acid and alkaline liquid material into the powder for mixing. 2. APPLICATION OF TWIN-SCREW CONE MIXER

3. TECHNICAL PARAMETERS

4. PICTURES picture 1

picture 2

blades for twin-screw cone mixer

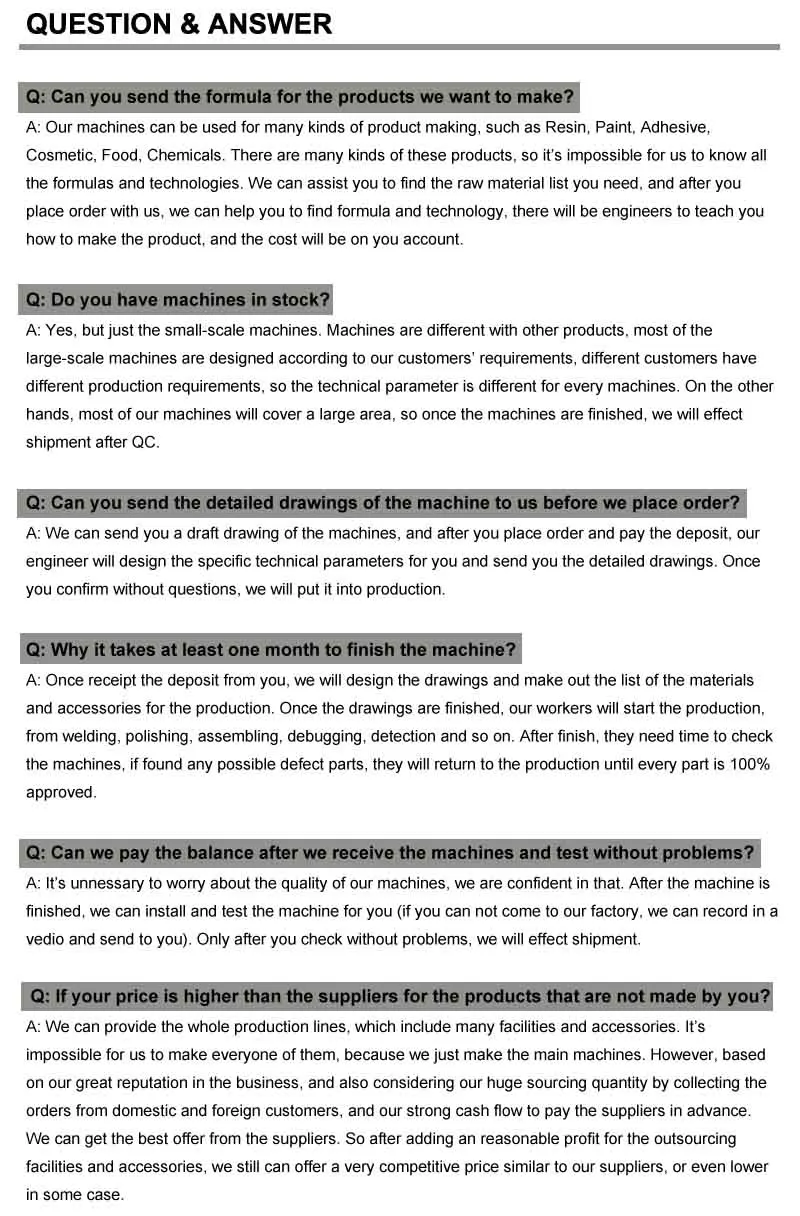

FAQ

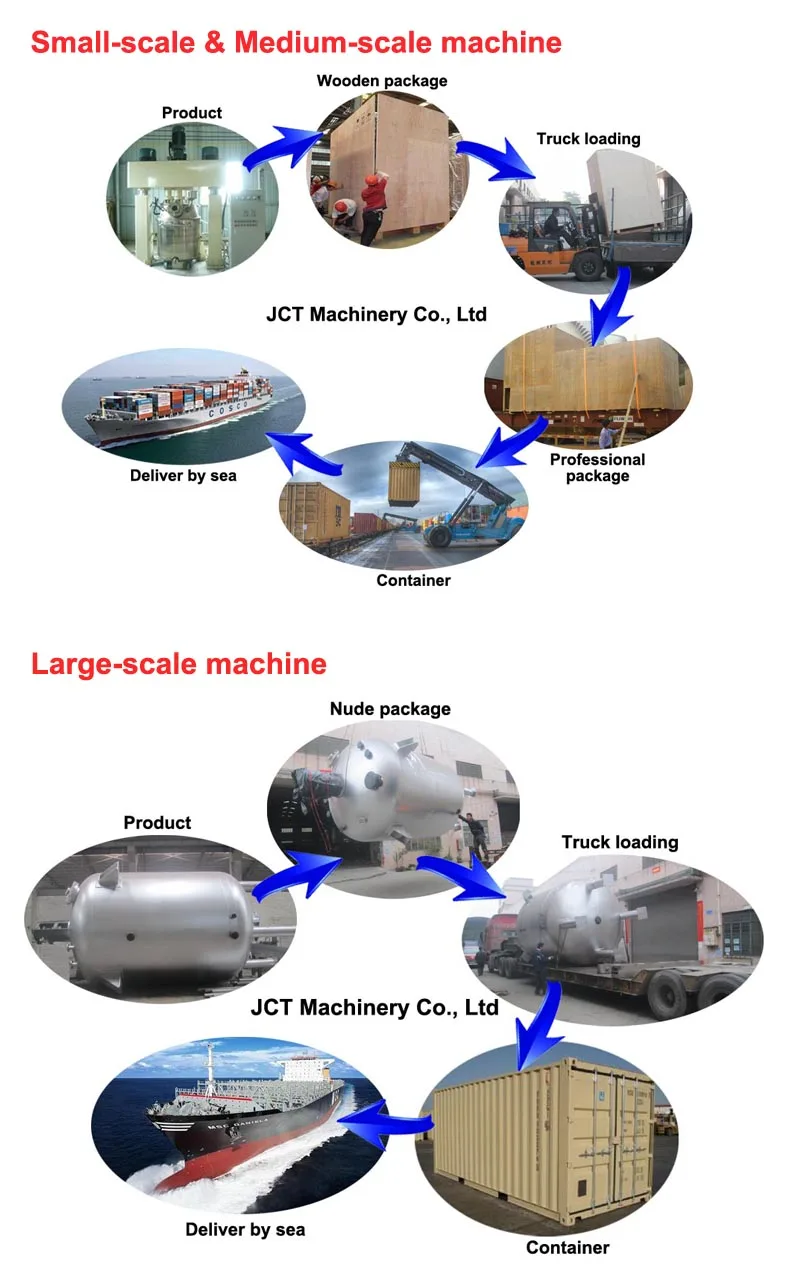

Packaging & Shipping

Company Information

5. WHY CHOOSE US Quality-assurance

Professional Sales team & Technology support & Strict processing department

Our Services

6. OUR CUSTOMERS

|

|

omo laundry detergent powder making machine

Product Description

1. INTRODUCTION Twin-screw cone mixer is a new and efficient mixing equipment, especially for powder mixing. Widely use for Chemicals, pharmaceuticals, pesticides, fertilizers, dyes, metallurgy, mining, food, monosodium glutamate, feed and other industries. Suitable for solid - solid (powder and powder) mixing, solid - liquid (powder and liquid) mixing. 1. Mixing Method: Standard Twin-screw cone mixer has two stirring spirals. According to the requirements for production, you can choose single spiral (one long spiral), double spirals (a long and a short asymmetrical spirals) and three spirals (two short and one long symmetrical spirals). 2. Cooling and Heating System: Can equip with outer jacket for heating or cooling. Usally use water for cooling, steam/ thermal oil/ electric for heating. 3. Liquid-adding Mixing: Install liquid jet pipeline in the intermediate shaft of the mixer, connect the atomizing nozzle, which can adding liquid into the mixer; By selecting a specific material, you can add the acid and alkaline liquid material into the powder for mixing. 2. APPLICATION OF TWIN-SCREW CONE MIXER

3. TECHNICAL PARAMETERS

4. PICTURES picture 1

picture 2

blades for twin-screw cone mixer

FAQ

Packaging & Shipping

Company Information

5. WHY CHOOSE US Quality-assurance

Professional Sales team & Technology support & Strict processing department

Our Services

6. OUR CUSTOMERS

|

|

omo laundry detergent powder making machine

Product Description

1. INTRODUCTION Twin-screw cone mixer is a new and efficient mixing equipment, especially for powder mixing. Widely use for Chemicals, pharmaceuticals, pesticides, fertilizers, dyes, metallurgy, mining, food, monosodium glutamate, feed and other industries. Suitable for solid - solid (powder and powder) mixing, solid - liquid (powder and liquid) mixing. 1. Mixing Method: Standard Twin-screw cone mixer has two stirring spirals. According to the requirements for production, you can choose single spiral (one long spiral), double spirals (a long and a short asymmetrical spirals) and three spirals (two short and one long symmetrical spirals). 2. Cooling and Heating System: Can equip with outer jacket for heating or cooling. Usally use water for cooling, steam/ thermal oil/ electric for heating. 3. Liquid-adding Mixing: Install liquid jet pipeline in the intermediate shaft of the mixer, connect the atomizing nozzle, which can adding liquid into the mixer; By selecting a specific material, you can add the acid and alkaline liquid material into the powder for mixing. 2. APPLICATION OF TWIN-SCREW CONE MIXER

3. TECHNICAL PARAMETERS

4. PICTURES picture 1

picture 2

blades for twin-screw cone mixer

FAQ

Packaging & Shipping

Company Information

5. WHY CHOOSE US Quality-assurance

Professional Sales team & Technology support & Strict processing department

Our Services

6. OUR CUSTOMERS

|

|

omo laundry detergent powder making machine

Product Description

1. INTRODUCTION Twin-screw cone mixer is a new and efficient mixing equipment, especially for powder mixing. Widely use for Chemicals, pharmaceuticals, pesticides, fertilizers, dyes, metallurgy, mining, food, monosodium glutamate, feed and other industries. Suitable for solid - solid (powder and powder) mixing, solid - liquid (powder and liquid) mixing. 1. Mixing Method: Standard Twin-screw cone mixer has two stirring spirals. According to the requirements for production, you can choose single spiral (one long spiral), double spirals (a long and a short asymmetrical spirals) and three spirals (two short and one long symmetrical spirals). 2. Cooling and Heating System: Can equip with outer jacket for heating or cooling. Usally use water for cooling, steam/ thermal oil/ electric for heating. 3. Liquid-adding Mixing: Install liquid jet pipeline in the intermediate shaft of the mixer, connect the atomizing nozzle, which can adding liquid into the mixer; By selecting a specific material, you can add the acid and alkaline liquid material into the powder for mixing. 2. APPLICATION OF TWIN-SCREW CONE MIXER

3. TECHNICAL PARAMETERS

4. PICTURES picture 1

picture 2

blades for twin-screw cone mixer

FAQ

Packaging & Shipping

Company Information

5. WHY CHOOSE US Quality-assurance

Professional Sales team & Technology support & Strict processing department

Our Services

6. OUR CUSTOMERS

|

Please feel free to contact us by email or the form below, we will soon reply within 24 hours.

- Mold glue production line

- Paint production line

- Neoprene adhesive production line

- Liquid silicone rubber production line

- Complete production equipment of Alkyd resin

- Acrylic emulsion production line

- vulcanized silicone rubber production line

- Graft adhesive production line

- Hot melt adhesive production line

- Silicone sealant production line

Related Suggestion

Related Suggestion

● Paint Mixer Blade | JCT Machinery

Jul 22,2024

Jul 22,2024

Tel

Tel

Email

Email

Address

Address

Donglian Jincheng Industrial Zone, Danzao Town, Nanhai District, Foshan City, Guangdong Province, China

CN

CN

HOME

HOME