Let's we choose suitable twin screw blender !

May 05,2017

May 05,2017

JCT

JCT

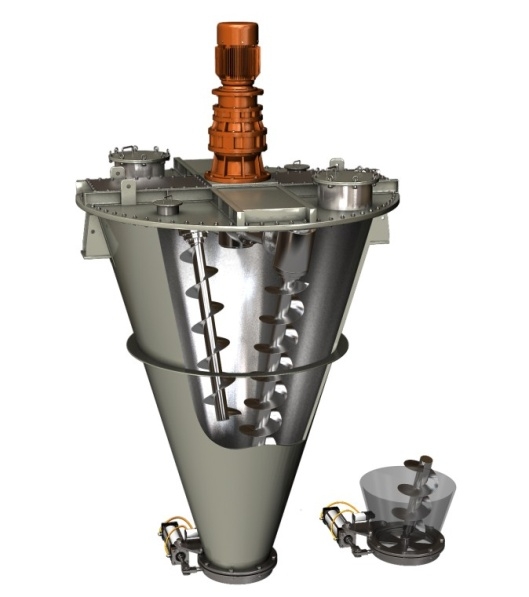

This is worldwide acknowledged as the industrial standard twin screw blender。

First, the applicable characteristics of twin screw blender generally have five points:

1. Suitable for the proportion of material disparity, powder particles quite large material;

2. Suitable for ceramic glaze mixing process is mild, the material particles will not be fed or broken;

3. The heat-sensitive materials will not produce overheating;

4. In the powder - powder mixing process, it is very convenient to add the conditions required for the liquid or set up to a number of spray mouth device;

5. The bottom of the dislocation valve easy to discharge, because the bottom of the screw without a fixed device, so there will be no pressure phenomenon.

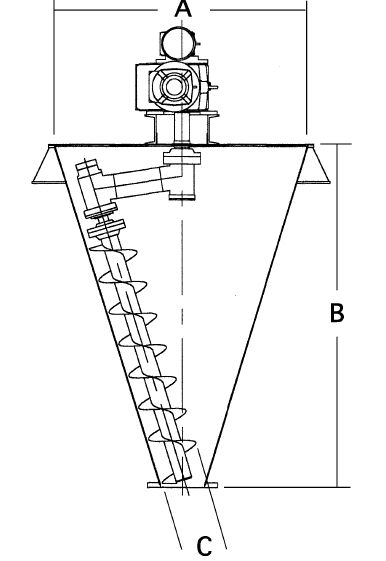

1.To determine the volume of each batch of mixed material, ranging from 0.1-20 cubic meters, select the appropriate specifications of the equipment.

2.Select the equipment to produce materials, material points: contact with the material part, not with the material contact part of the other parts of the equipment to maintain the original material. (Material based on the nature of the material, working conditions, health level and other factors, conventional carbon steel, 304 / 316L / 321 stainless steel) (material selected according to the requirements to determine the surface treatment requirements)

3.According to the proportion of the material, liquidity and other properties, as well as start the standard to determine the configuration of the drive capability. (Start standard points: overload start, no load start)

4.According to the actual process, increase the auxiliary function components, such as spray, heating / cooling, and so on.

5.The design of the equipment requirements, such as feeding mouth, clean up the mouth, vent and so on

6.Choose the discharge mode and drive the way, sub-manual, pneumatic, electric

Any twin screw mixer problem you can contact with us!

CN

CN

HOME

HOME This is our high speed disperser paint color mixer machine gives custmers the attitude of service !

This is our high speed disperser paint color mixer machine gives custmers the attitude of service !  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address