The best stainless steel pressure vessel in stainless vessel manufacturer JCT!

May 16,2017

May 16,2017

JCT

JCT

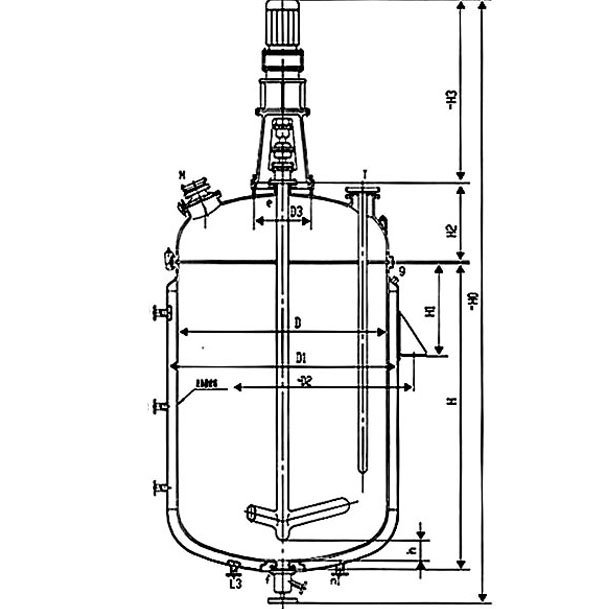

Stainless steel pressure vessel is the main chemical reaction of the typical production equipment, which is widely used in resins, adhesives, paint, cosmetics, pharmaceutical and other chemical production. To break down or combined the materials through mixing, filling and cooling, to promote the reaction of polymerization. The stainless steel pressure vessel consists of body, gears, mixing devices, heating devices, cooling devices, seal composition and some corresponding auxiliary equipment: distillation column, condenser, water separator, collecting cans, filters ect.

Also pay attention to these matters! Because the machine as an atmospheric stainless steel pressure vessel, in the production operation should pay attention to the maintenance of the relevant matters, but also pay attention to other production operations related matters:

1.The controller should be properly connected to the front and the zero line, the ground wire is necessary to ground, wiring operations should be carried out without power transmission. To prevent oil, gas and other flammable and explosive environment in the operation of the controller. After the controller is connected to the power supply, do not pull any contact with any plug during operation. When the reactor is equipped, the explosion vent is connected to the outside via piping.

3.Do not change the temperature in the heating process, change the temperature set value.

4.The timing of the stainless steel pressure vessel, a variety of appearance and explosive discharge equipment, hot oil to detect the oil level to ensure that equipment can be normal operation.

5.Isolation sets of abnormal static movement, the need to stop the pressure to see the mixing system. Mixing shaft swing too much should be replaced in time bearing or sliding sleeve.

7.The speed shows the correct detection orientation should not be adjusted, the orientation has been adjusted at the factory.

If you are interested about stainless steel pressure vessel welcome to contact us!

CN

CN

HOME

HOME To make a good toothpaste

To make a good toothpaste  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address