Ribbon Mixer - A Classic Equipment Choice For Efficient And Uniform Mixing | JCT Machinery

Nov 26,2025

Nov 26,2025

JCT

JCT

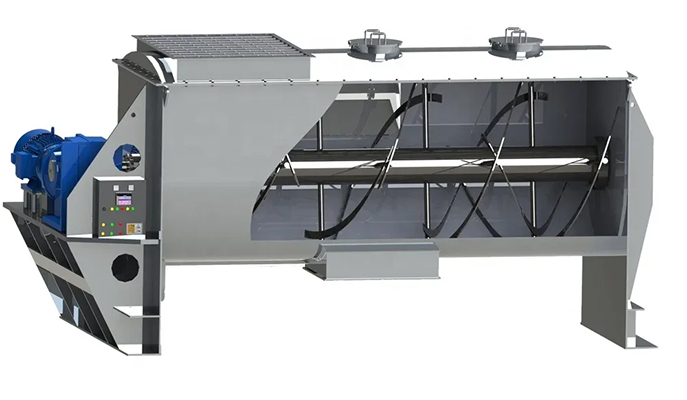

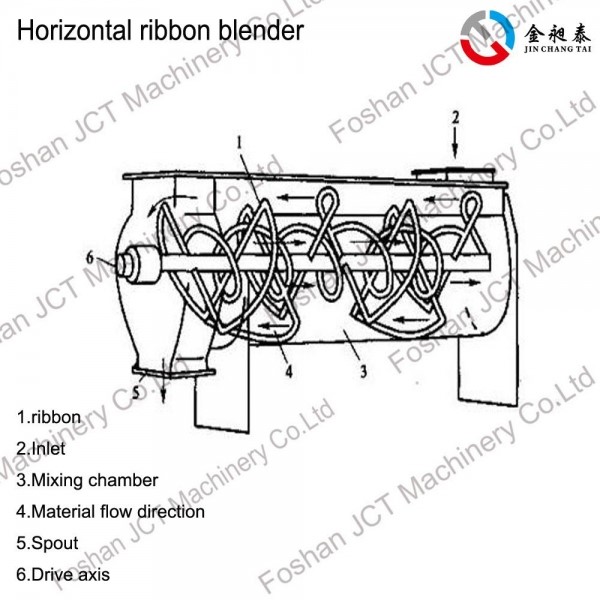

Ribbon Mixer Working Principle

The equipment adopts a U-shaped cylinder + inner and outer double-layer ribbon structure:

- Outer ribbon pushed the material towards the sides.

- Inner ribbon pushed the material towards the center.

- Two flow directions are opposite, creating strong onvective mixing.

Through this three-dimensional circulating flow, the materials achieve a high degree of uniformity in a short time, making it especially suitable for mixing powders wih small amounts of liquids.

Ribbon Mixer Main Structure

1. Double-layer ribbon structure

Faster mixing speed

Fewer dead spots

Suitable for lightweight powders, easily hygroscopic powders, and materials with uneven additive ratios.

2. U-shaped cylinder design

Allows for a more rational material mixing flow path, reducing retention.

3. High-efficiency power system

Integrated motor and gearbox drive

Low energy consumption, high stability, and easy maintenance.

4. Multiple discharge methods available

- Pneumatic flap valve

- Manual ball valve

- Butterfly valve

Can be selected according to material viscosity and powder fluidity.

5. Optional liquid spraying system

For powders requiring the addition of a small amount of liquid, a spray gun system can be selected to achieve a more uniform wet mixing process.

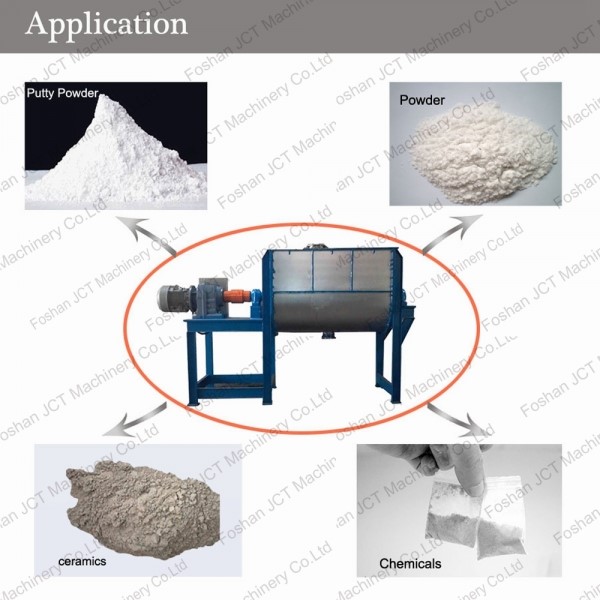

Applications of Ribbon Mixer

Powder mixing:

- various resin powders

- building material powders

- coating pigments and fillers

- food additive powders

- fillers, additives, calcium carbonate, etc.

Powder-liquid mixing:

- pre-mixing of white emulsion powder

- mixing of insecticides and feed additives

- mixing of powder materials in hot melt glue formula

Other processes:

- high-temperature material mixing (with jacket option)

- mixing of easily airborne powders (with dust removal port option)

- mixing of materials prone to clumping (with optional blades or crushing device)

Advantages of Ribbon Mixer

- High mixing uniformity (CV≤5%)

- High efficiency

- Simple operation and easy maintenance

- Low cost and excellent value for money

- Customizable

Why Choose JCT Ribbon Mixer?

- 20+ years of experience in manufacturing chemical mixing equipment

- Owned factory, high processing precision, short delivery time

- Familiar with formula and process in industries such as resins, coatings and adhesives

- Can provide complete production line solutions, not just individual equipment

JCT not only provide equipment, but also offer:

- factory layout planning

- automation upgrade solutions

- integration of feeding, weighing and packaging systems

- overseas installation and commissioning support

Truly enabling customers to easily establish a large-scale, mass-production mixing line.

CN

CN

HOME

HOME Characteristics And Applications Of Bulk Hot Melt Glue | JCT Machinery

Characteristics And Applications Of Bulk Hot Melt Glue | JCT Machinery  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address