The impact of 4 factors making PVC preparation

May 13,2017

May 13,2017

JCT

JCT

1) temperature control high-speed kneading machine speed is usually between 900-2000r / min, the material in the machine high-speed friction heat, in the mixing process, the temperature control is very important, the general temperature control to do the following:

① must ensure that the cooling water temperature below 15 ℃;

② PVC resin and additives into the kneader, the immediate stirring, the use of its friction temperature, when the temperature reaches 120 ℃ or so when the nesting to the cold mix machine;

③ hot material mixed in a cold mix for a certain time, when the material temperature below 45 ℃ can open the cold mix gate discharge material.

2) mixing time materials in the mixing process experienced by the density changes, homogenization and partial gelation process, all need some time to complete. Mixing time is too short, will make the extrusion process becomes difficult, material melting time becomes longer, product quality deterioration. But the time is too long, the temperature will rise too high, easy to cause decomposition of the material discoloration, and energy consumption, low production efficiency.

3) feeding order hard PVC resin formula more components, choose a reasonable feeding order is very important. The order of selection should be conducive to the role of additives to play, to avoid the poor synergistic effect of additives, but also help to improve the dispersion rate.

If the external lubricant is added too early, it will cover the outer layer of PVC particles, hinder the re-combination of PVC particles, thereby reducing the degree of compactness, degree of homogenization and gelation rate, so the external lubricant is usually added in the late mixing; As well as processing aid ACR easy to adsorb stabilizer and liquid additives, affect its stability and plasticizing effect, it should also be added after the stabilizer.

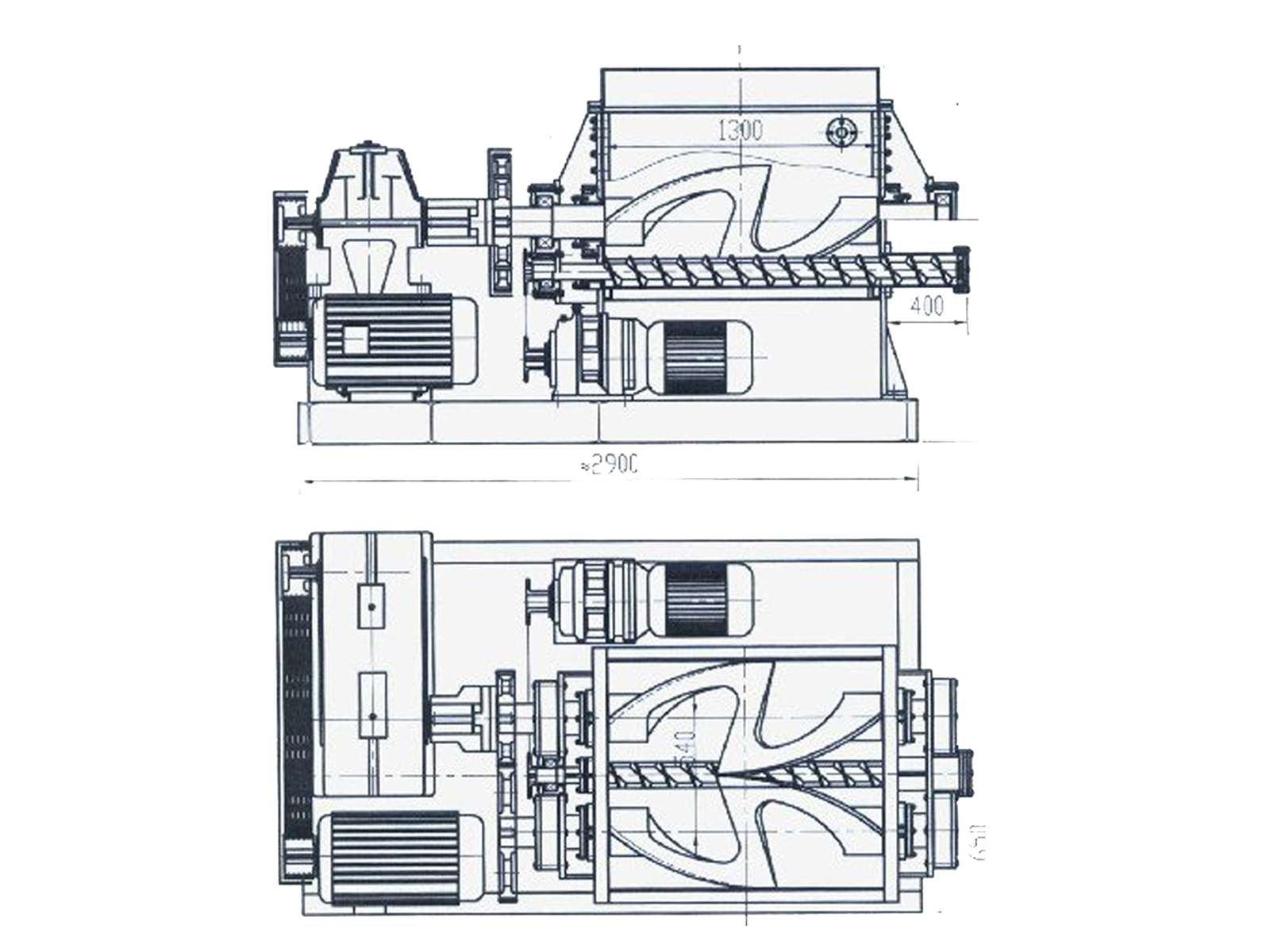

PVC mixing machine is an ideal equipment, design for mixing, kneading, crushing, dispersing high viscosity plastic materials, and has good performance in uniform mixing, no dead ends and high efficiency kneading. pvc mixing machine has six major components. kneading part, base part, the transmission system, vacuum system, hydraulic system, electric control system, etc. Place of all the contact material is made of stainless steel.

If you are interested in PVC mixing machine please contact us!

CN

CN

HOME

HOME A Great Cause Should Be Pursured For Common Good !

A Great Cause Should Be Pursured For Common Good !  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address