Polyalkyd Resin Reactor | JCT Machinery

Jul 02,2025

Jul 02,2025

JCT

JCT

Main Features of Polyalkyd Resin Reactor

1. Structural design

Vertical or horizontal reactor, the most common is vertical jacketed structure.

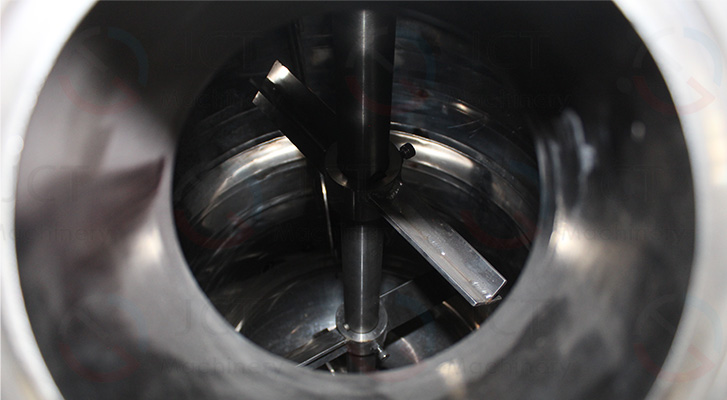

The stirring system is usually frame type+scraper stirring, and can also be equipped with anchor stirring+scraper, which is suitable for high viscosity materials.

The lid of reactor is equipped with interfaces such as condenser, vacuum port, feed port, discharge port, temperature measuring port, etc., which are convenient for multi-point process control.

2. Heating method

You can choose thermal oil jacket heating or external coil heating, with a wide temperature control range (150-260℃).

The heating system cooperates with the condensation and dehydration system to promote the reaction in the direction of polycondensation.

3. Material

The commonly used materials are SS304/316.

For special systems, carbon steel+lining enamel can be selected.

The inner wall needs to be mirror polished or electropolished to prevent the resin from sticking to the wall.

4. Condensation and dehydration system

Equipped with vertical condenser + water separator (oblique or U-shaped), used for efficient condensation recovery or separation of by-product water or alcohol in high-temperature reaction.

It helps to control molecular weight and improve the quality of finished resin.

5. Vacuum and pressure control

It is often equipped with a vacuum pump or vacuum interface, which can be operated under a certain negative pressure to increase the reaction rate and reduce side reactions.

If the production system requires positive pressure, the pressure vessel structure can be designed to meet safety regulations.

CN

CN

HOME

HOME Tire Repair Sealant Production Line | JCT Machinery

Tire Repair Sealant Production Line | JCT Machinery  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address