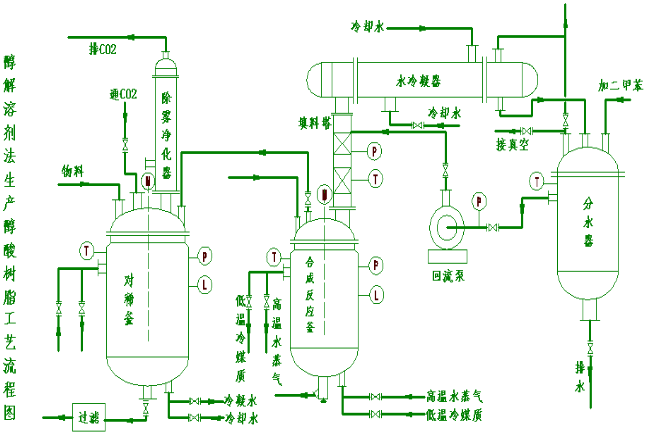

Alkyd resin production process

May 25,2020

May 25,2020

JCT

JCT

Alkyd resin production process

Alkyd resin is a condensation of polyhydric alcohol (usually glycerin, trimethylolpropane, trimethylolethane, pentaerythritol, etc.) and polybasic acid (mainly phthalic anhydride, isophthalic anhydride, trimellitic anhydride, etc.) It is a kind of polymer compound with polyester as the main chain and fatty acid as the side chain.

Process

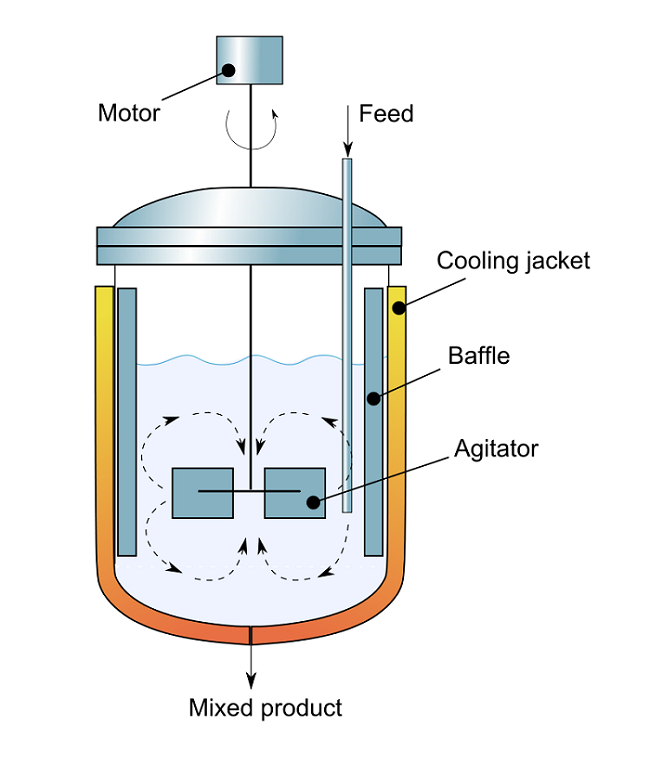

1. Alcoholy reaction: during alcoholysis, some raw materials such as glycerin and LiOH catalyst are added to the reaction kettle for stirring reaction, and at the same time, CO2 is passed in for protection to prevent the oxidation of oil due to excessive temperature and affect the product quality. Heating method: steam or high pressure water circular heating.

2. Polyesterification reaction: xylene and water form an azeotrope and evaporate to bring out the esterified water. After the oil-water separation of the water separator, it flows back to the reaction kettle. This is repeated to promote the polyesterification reaction to produce alcohol. Acid resin. Add 6% of xylene, polycondensation between 210 ~ 240 ℃.

3. Dilution: After the reaction is completed, the temperature is lowered, the solvent xylene or other solvents required by the commodity are added, and the solvent is added under constant stirring to complete the dilution.

4. Filtration: Filter by centrifuge.

JCT has designed and manufactured alkyd resin equipment for more than 20 years. It has provided many production facilities for manyalkyd resin factories, and has met many alkyd resin technology engineers, and has strong technical team.

Contact information:

If you need to know the detailed equipment configuration, production technology, production process, please contact us.

website : www.nhjct.cn

telephone:+86-0757- 8625 3526;

Email:[email protected]

Mobile: 0086-13929992673(WhatsApp)

18028192316

CN

CN

HOME

HOME Neoprene equipment maintenance method

Neoprene equipment maintenance method  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address