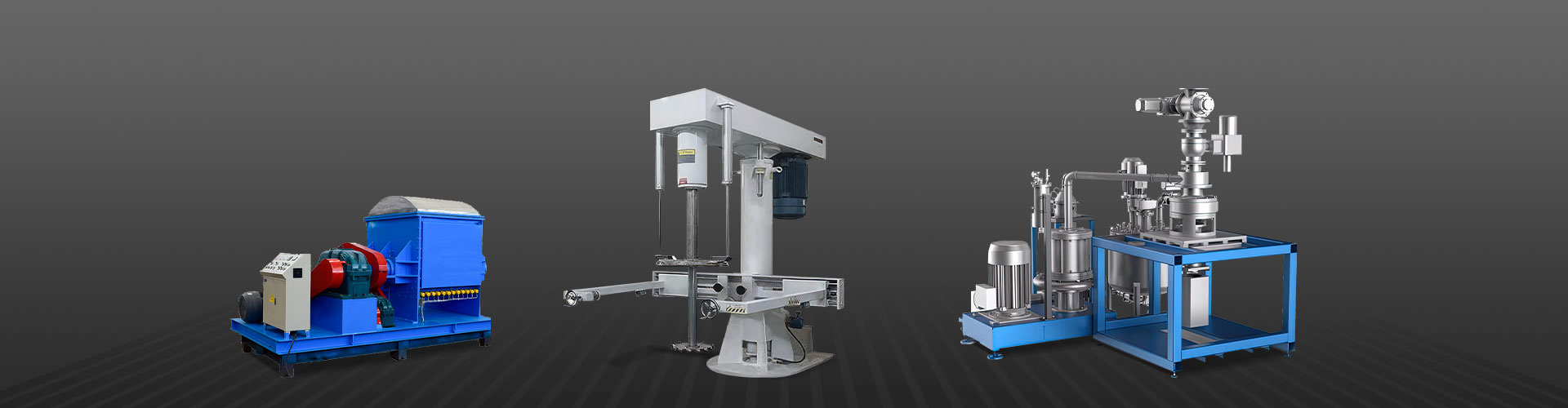

1.Production line equipment configuration:

Reaction kettle, condenser, dispersing kettle, filter, filling machine, steam furnace, water cooling system, material pump, Raw material tank,Finished storage tank,Metering tank,etc.

2.Production process:

1)All kinds of raw materials are prepared according to the technical formula.

2)The solvent, the resin and the metal oxide are added to the reactor for about 2 hours mixing.

3)According to the formula requirements to join EAC, Different kinds of chloroprene rubber, resin,antioxidant etc.;

4)The mixture is homogeneous and completely dissolved.

5)Sampling inspection, qualified after packing

The polychloroprene adhesive has high cohesive strength, heat resistance, oil resistance and aging resistance, and has good bonding effect on metal and non-metal. For woodworking, furniture, shoemaking, construction, electronics, textile, transportation, machinery and other departments. It can be made into contact adhesive.

Production line characteristic:

1 ) JCT machinery Equipment Co., Ltd. is a professional manufacturer specializing in design, production, installation and commissioning. It has more than 20 years of design and production experience, advanced design, well made,the products are sold to all over the world.

2 ) The Neoprene adhesive production line designed by JCT is communicated with a number of experienced grafted glue technology engineers. After design, the production line has high production efficiency and low production cost. It can realize semi-automatic or automatic control according to different customer requirements.

Production line specifications:

1)500L-1500L Grafted adhesive production line;

2)2000L-3000L Grafted adhesive production line;

3)4000L-6000L Grafted adhesive production line;

4)8000L-12000L Grafted adhesive production line;

It can be designed according to the actual needs.

Contact information:

If you need to know the detailed equipment configuration, production technology, production

process, please contact us.

Email:[email protected]

Mobile: 0086-181 3837 3963(WhatsApp, Wechat)

Address: Donglian Jincheng Industrial Zone, Danzao Town, Nanhai, Foshan, Guangdong, China.

Product line

Product line sigma mixer

sigma mixer mixing tank

mixing tank Ribbon blender

Ribbon blender kneading machine

kneading machine Reactors

Reactors High-Shear Mixers

High-Shear Mixers

CN

CN

HOME

HOME

Related Suggestion

Related Suggestion

Jul 25,2024

Jul 25,2024

Tel

Tel

Email

Email

Address

Address