Mold adhesive production line is systematically designed around precise metering, uniform mixing, vacuum degassing, and stable dispensing to ensure that the mold adhesive has excellent fluidity, density and molding consistency, meeting the requirements of precision mold replication and industrial molding.

Manufacturing challenges in mold adhesive production

- High material viscosity, prone to trapping air bubbles

- High requirements for mixing uniformity

- Finished product is extremely sensitive to air bubbles and impurities

- Strict requirements for formula and process stability

The mixing capabilities, vacuum performance, and control precision of the mold adhesive production line equipment we provide all meet our customers' requirements.

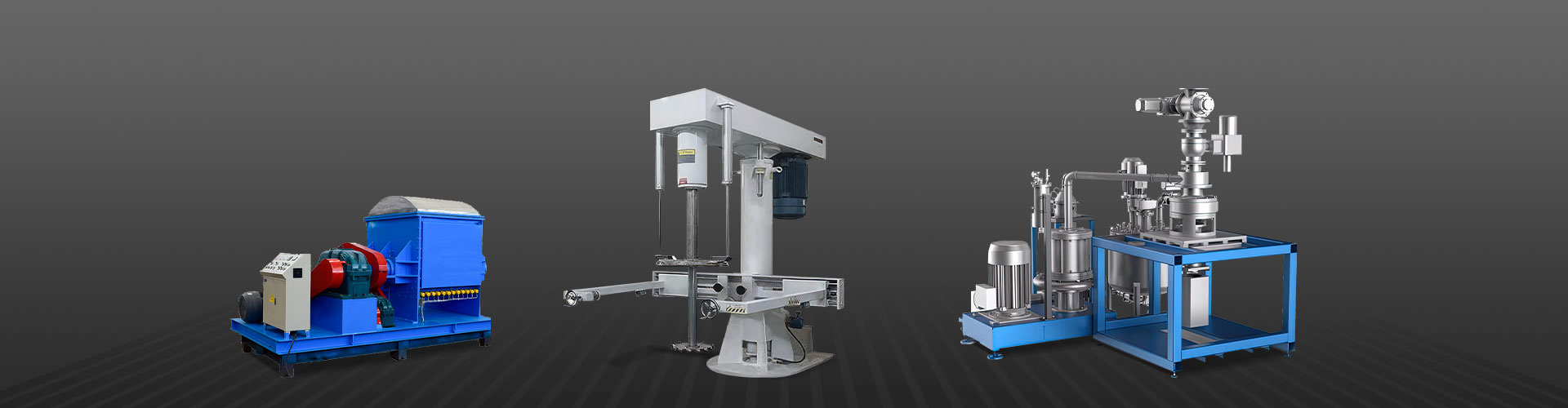

Mold Adhesive Production Line Main Equipment Configuration

1. Sigma mixer

Supports high-viscosity and high-filler systems

Can be configured with a powered wall-scraping structure

2. Vacuum system

Integrated vacuum mixing and degassing

Improves product density and surface quality

3. Metering and feeding system

Precise metering of liquids and powders

Reduces human error and improves consistency

4. Temperature control system

Jacketed heating and cooling

Stabilizes the rheological properties of the mold compound

5. Discharge and packaging system

Bottom valve discharge / screw extrusion

Connects to filling or packaging equipment

Complete Mold Adhesive Production Line Turnkey Services

- Process scheme design

- Main and auxiliary equipment matching

- Automation control system

- Installation, commissioning and technical support

Applicable Product Types:

- Silicone rubber mold compounds

- PU mold compounds

- Elastomer mold compounds

- Industrial replication and precision casting materials

Product line

Product line sigma mixer

sigma mixer mixing tank

mixing tank Ribbon blender

Ribbon blender kneading machine

kneading machine Reactors

Reactors High-Shear Mixers

High-Shear Mixers

CN

CN

HOME

HOME

Related Suggestion

Related Suggestion

Jul 25,2024

Jul 25,2024

Tel

Tel

Email

Email

Address

Address