1. Features of silicone production line

1) Foshan Nanhai Jinchangtai Machinery Equipment Co., Ltd. is a manufacturer of chemical machinery and equipment for research, development, design, manufacturing, installation and commissioning. It has more than 15 years of experience in the design and manufacture of liquid silicone production equipment.

2) The silicone equipment produced by Jinchangtai Machinery Equipment Co., Ltd. has the characteristics of advanced design and sophisticated manufacturing, reasonable structure, convenient operation, low labor cost, high production efficiency, and good product quality. It is suitable for all kinds of silicone.

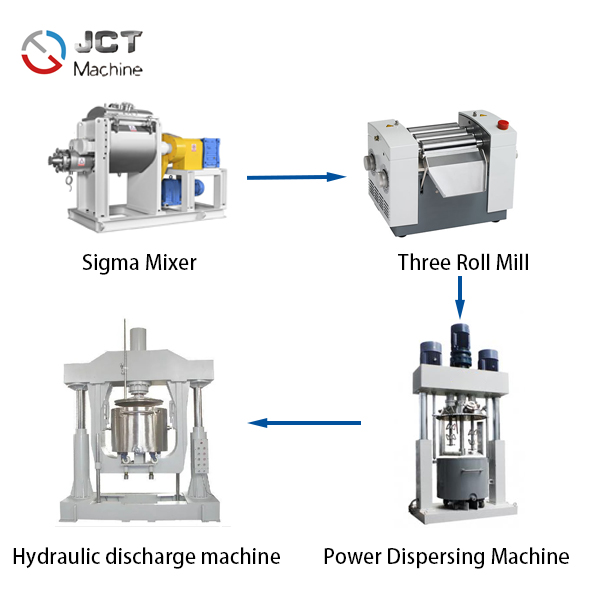

2. Equipment configuration of silicone production line

1) Vacuum kneader;

2) High viscosity pump,

3) Base material storage tank,

4) Heating system (according to actual needs),

5) Vacuum system,

6) Three-roll mill,

7) Multifunctional dispersing mixer or planetary mixer,

8) Hydraulic discharge machine,

9) Cooling system.

3. Silicone production process:

1) The preparation of raw materials is carried out according to the formula. Add the kneader, and the powder raw materials should be added several times and mixed evenly. Heating and heating, start the vacuum system, draw moisture from the material.

2) The base material reaches the base material storage tank through a high-viscosity pump, and these materials are slowly added to the three-roll grinder to meet the fineness requirements.

3) After grinding the substrate, put the material into the mixing drum. Then add other ingredients and paste.

4) Push the mixing drum into the multifunctional dispersing machine or planetary mixer to start mixing and high-speed dispersion. At the same time, the vacuum system is activated to extract moisture and air from the material. Start the cooling system to control the temperature of the material.

5) After the production is completed, push the mixing cylinder into the hydraulic discharge machine and divide it into packaging drums.

6) Pack the finished product into the warehouse.

4. Technical conditions of silicone rubber production line:

1) 10-30 tons/body silicone rubber production line;

2) 20-60 tons/month silicone rubber production line;

3) 40-120 tons/month silicone rubber production line;

4) 60-180 tons/month silicone rubber production line;

After the liquid silica gel is made into a mold, various liquid materials can be poured into the mold to form: for example, wax resin, cement, plaster, soap, etc., to replicate anything that has a solid body.

1. Features of silicone production line

1) Foshan Nanhai Jinchangtai Machinery Equipment Co., Ltd. is a manufacturer of chemical machinery and equipment for research, development, design, manufacturing, installation and commissioning. It has more than 15 years of experience in the design and manufacture of liquid silicone production equipment.

2) The liquid silicone equipment produced by Jinchangtai Machinery Equipment Co., Ltd. has the characteristics of advanced design and sophisticated manufacturing, reasonable structure, convenient operation, low labor cost, high production efficiency, and good product quality. It is suitable for all kinds of liquid silicone.

2. Equipment configuration of liquid silicone production line

1) Vacuum kneader;

2) High viscosity pump,

3) Base material storage tank,

4) Heating system (according to actual needs),

5) Vacuum system,

6) Three-roll mill,

7) Multifunctional dispersing mixer or planetary mixer,

8) Hydraulic discharge machine,

9) Cooling system.

3. Production process of liquid silica gel:

1) The preparation of raw materials is carried out according to the formula. Add the kneader, and the powder raw materials should be added several times and mixed evenly. Heating and heating, start the vacuum system, draw moisture from the material.

2) The base material reaches the base material storage tank through a high-viscosity pump, and these materials are slowly added to the three-roll grinder to meet the fineness requirements.

3) After grinding the substrate, put the material into the mixing drum. Then add other ingredients and paste.

4) Push the mixing drum into the multifunctional dispersing machine or planetary mixer to start mixing and high-speed dispersion. At the same time, the vacuum system is activated to extract moisture and air from the material. Start the cooling system to control the temperature of the material.

5) After the production is completed, push the mixing cylinder into the hydraulic discharge machine and divide it into packaging drums.

6) Pack the finished product into the warehouse.

1) 10-30 tons/mmonth mold glue production line;

2) 20-60 tons/month mold glue production line;

3) 40-120 tons/month mold glue production line

4) 60-180 tons/month mold glue production line

It can be designed according to the act

Contact information:

If you need to know the detailed equipment configuration, production technology, production

process, please contact us.

Email:[email protected]

Mobile: 0086-181 3837 3963(WhatsApp, Wechat)

Address: Donglian Jincheng Industrial Zone, Danzao Town, Nanhai, Foshan, Guangdong, China.

Product line

Product line sigma mixer

sigma mixer mixing tank

mixing tank Ribbon blender

Ribbon blender kneading machine

kneading machine Reactors

Reactors High-Shear Mixers

High-Shear Mixers

CN

CN

HOME

HOME

Related Suggestion

Related Suggestion

Jul 25,2024

Jul 25,2024

Tel

Tel

Email

Email

Address

Address