Liquid Silicone Rubber Sigma Mixer Main Technical Parameters (reference)

| Volume |

5L-10000L |

| Propeller Type |

∑-shaped / custom low-shear propeller |

| Main Motor Power |

2.2-75kW |

| Speed Range |

0-60rpm (variable frequency) |

| Material |

SS304/316 |

| Surface Treatment |

Inner wall polishing, Ra≤0.4-0.8μm |

| Temperature Control |

Cooling water / heat transfer oil (optional) |

| Vacuum Degree |

≤-0.095MPa |

| Discharge Method |

Bottom discharge / hydraulic tilting discharge / screw discharge |

** Specific parameters are customized based on LSR formula, cleanliness level, and process requirements.

Suitable for Liquid Silicone Rubber Systems

- Two-component liquid silicone rubber

- Medical-grade liquid silicone rubber

- Electronic-grade liquid silicone rubber

- LSR materials for sealing and potting

- Food-grade liquid silicone rubber

Main Advantages of Liquid Silicone Rubber Sigma Mixer

- High uniformity kneading structure: Dedicated ∑-shaped/customized low-shear paddle design ensures thorough LSR mixing without introducing excessive air.

- Precise speed control: Low-speed, high-torque operation avoids localized overheating and performance fluctuations.

- Excellent sealing system: Adaptable to low-viscosity liquid silicone rubber, preventing leakage and external contamination.

- Strong vacuum degassing capacity: Effectively removers microbubbles generated during mixing, improving the appearance and physical properties of the finished product.

- Stable temperature control: Jacketed structure supports cooling or constant temperature, ensuring system stability before vulcanization.

- High batch consistency: Suitable for silicone rubber products with extremely high performance stability requirements.

Liquid silicone rubber (LSR) requires extremely high levels of uniformity in mixing, bubble control, and temperature stability. Compared to general mixing equipment, liquid silicone rubber sigma mixer is better suited to the characteristics of LSR processes in terms of paddle design, sealing structure, and vacuum control, which can effectively improve the consistency, reliability, and yield of the products.

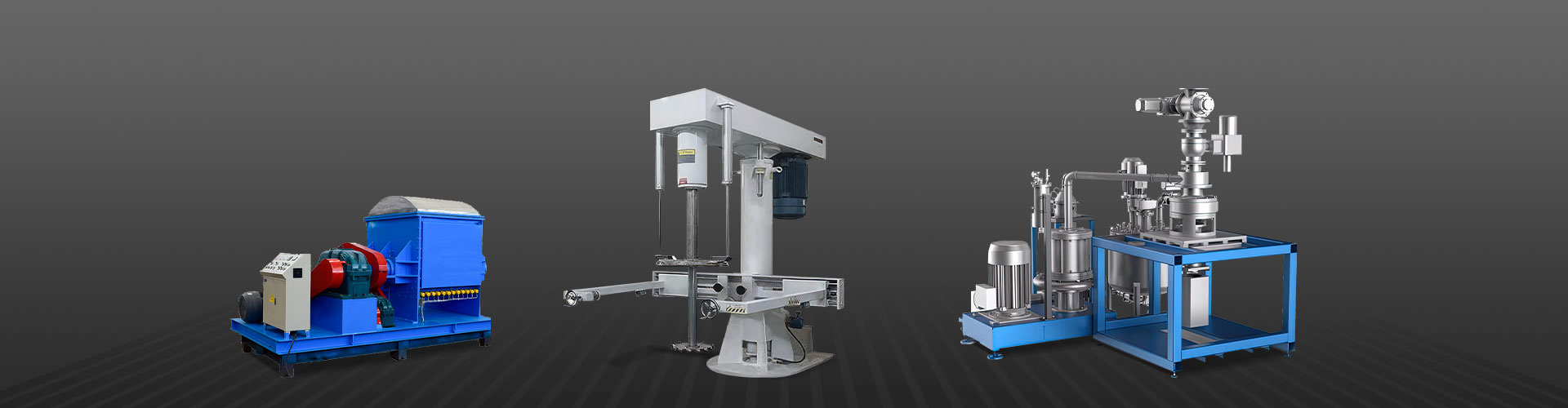

Product line

Product line sigma mixer

sigma mixer mixing tank

mixing tank Ribbon blender

Ribbon blender kneading machine

kneading machine Reactors

Reactors High-Shear Mixers

High-Shear Mixers

CN

CN

HOME

HOME

Related Suggestion

Related Suggestion

Jul 25,2024

Jul 25,2024

Tel

Tel

Email

Email

Address

Address