Email: [email protected]

Phone:0086-13929992673

Address: Wufuwei Industrial Zone,Pingzhou,Nanhai,Foshan,Guangdong,China

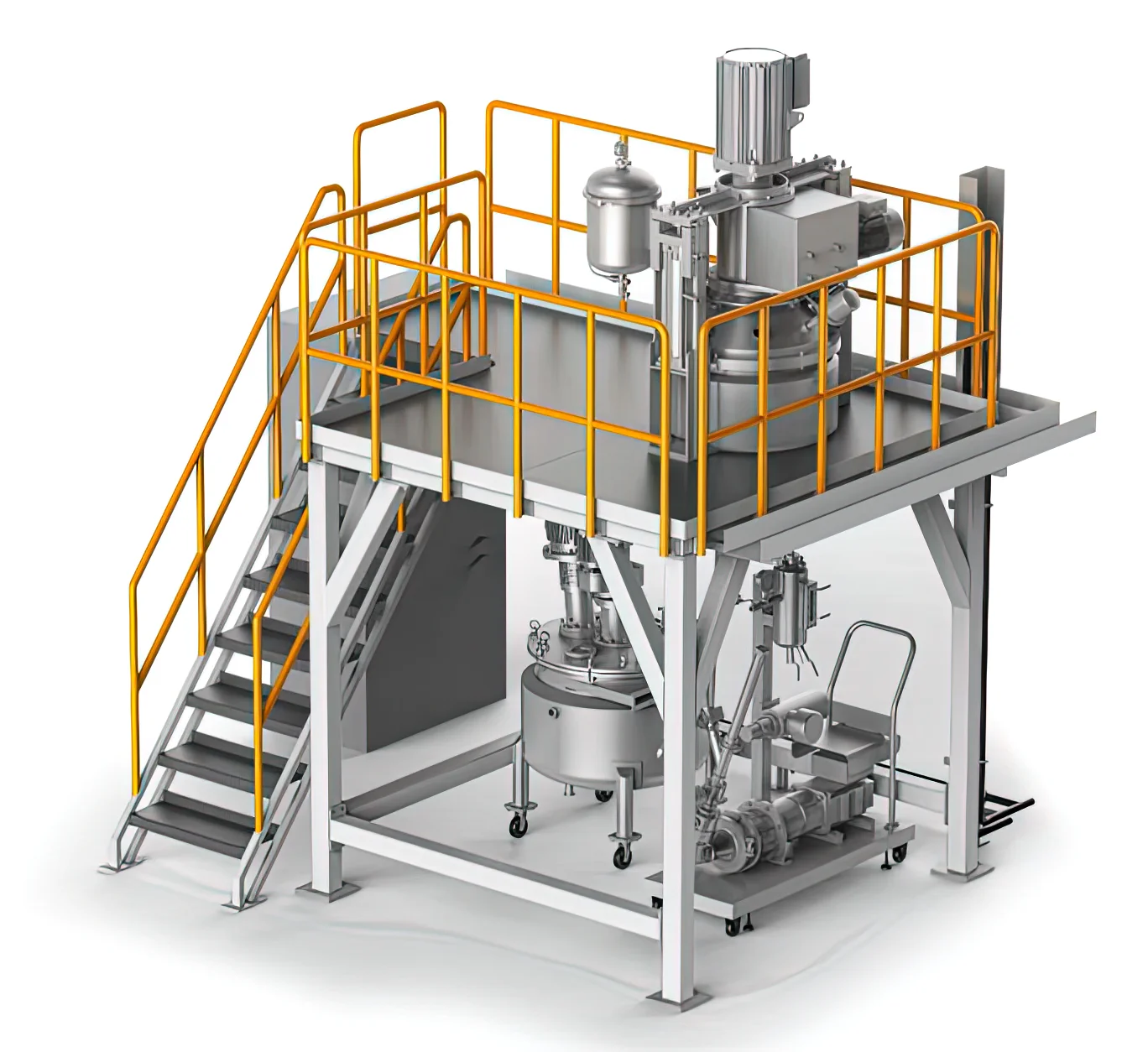

Battery slurry vacuum liquid mixer Lithium battery mixing storage tank factory

Author: JCT source: Datetime: 2023-01-13 16:52:29

Products Description

Lithium battery automatic production line

Lithium battery cathode material intelligent factory, the whole factory adopts a fully automatic production mode, the raw materials lithium nickelate, lithium cobaltate and lithium manganate are stirred evenly according to a certain ratio, quantitatively loaded into the ceramic box, and delivered to the kiln through the conveyor belt Carry out high-temperature sintering, three times of sintering and corresponding crushing and grinding, and finally produce ternary lithium battery positive electrode material powder. The equipment is connected by conveying lines, pipelines, pneumatic conveying equipment and climbing equipment.

Active material, conductive agent and binder powder pass through powder mixer After stirring evenly, import it into the mixing and dispersing machine, and the solvent and liquid conduct electricity The agent is injected from the circulation tank, and the powder and liquid are in the mixing and dispersing machine Mix and disperse, and circulate until the slurry is qualified.

|

PRODUCT APPLICATIONS |

|

|

Aluminum Oxide-Filled Silicone Gels |

Conductive thermal interface material for use in high-speed computer processor applications. |

|

Battery Pastes and Slurries |

Homogenous dispersion of the active material into the binder solution is critical for consistent battery performance. |

|

Conductive Inks |

Can be a blend of finely ground carbon black into high molecular weight resin. The more viscous solutions are not easily turned over by single shaft high-speed dispersers. |

|

Copper Pastes |

Used in screen-printing processes as part of multi-layered microchip production. Vacuum mixing is of benefit for this application as air in the product can cause defects in screened wires. |

|

Encapsulation Materials |

Protective materials used to isolate circuits from moisture and other harmful contaminants, provide electrical insulation for high voltages and also protect the circuit from thermal and mechanical stresses. |

|

Epoxy Insulators |

When prepared in single shaft mixers, heating of powder ingredients is necessary and solids are slowly added to the top of liquid epoxy resin and hardeners. |

|

Ferrite Compounds |

Our Double Planetary Mixers with HV Blades are excellent equipment for manufacturers of battery, capacitors and power storage products utilizing Carbon Black Slurry and Ferrite in Binder technologies. |

|

Ferrite in Propylene |

in the manufacture of components for capacitors, ferrite powders are mixed into wax, copolymer and polypropylene binder. Downstream, the cooled mixture is broken up to smaller pieces for injection molding. |

|

Fuel Cell Powders |

an example is a lithium cake mixture, which functions as a porous, insulating, and chemically inert ceramic matrix inside the fuel cell. |

|

Solder Pastes |

Fusible metal alloys, melted at relatively low temperatures (120-450°C) to join metallic surfaces. |

|

Thick Film Inks |

Dispersion of very small particles of inorganic powders in a viscous liquid vehicle. The type of powder used determines the nature of the thick film ink; metals for conductors, metal oxides for resistors and dielectric glasses for insulating coatings. |

|

Tungsten Carbide Powders |

The JCT Double Planetary Mixer is extremely successful in blending a slurry of these extremely dense materials, then vacuum drying the batch to form a light, fluffy powder. |

Stand-alone production capacity ranks first in the world at 2500L/h

which can meet the annual production capacity demand of 6GWh

Lithium-ion battery high solid content pulping system-vertical kneader

The kneading time is only 1/3 of the traditional mixer, and it only takes 1h to do it Qualified finished slurry • 50% less floor space • Unit energy consumption is only 30% of traditional mixers • Especially suitable for the pulping of nano-scale anode and cathode materials, including nano-phosphoric acid Iron (manganese) lithium, hard-to-wet graphite negative electrode, silicon (oxygen) carbon negative electrode